Company

Start » Company

Everything From a Single Source

Manufactured by a strong team.

We are a company that is brimming with ideas, a production and development hub, a distribution centre, and service partners.

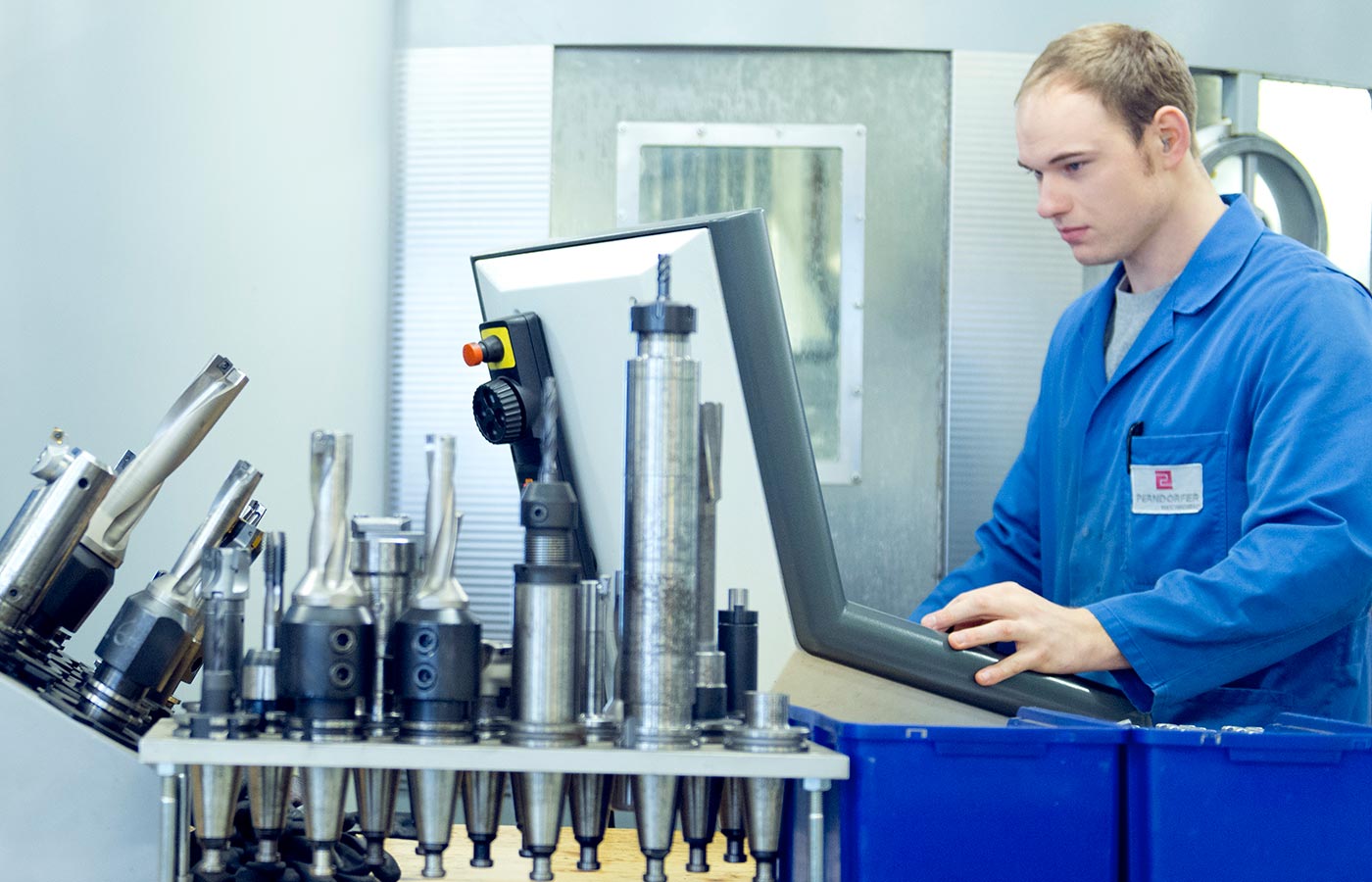

At Perndorfer everything is manufactured under one roof. As a family-run company, we always do our best. This is evident in our dealings with our clients, but, above all, in our products which are durable, long-lasting, and produced entirely in our production facility in Kallham. All of these factors have made our products a reliable partner for many years.

- Our company is family-owned and has ISO:9001 certification. At our location in Kallham (Upper Austria) we not only assemble, but also manufacture 90 percent of our parts ourselves.

- We build prototypes and deliver machines that are fitted exactly to client needs.

- We help the environment and help you save by continually refining our products.

- Our products can be viewed and tested in our new technology centre Perndorfer Cutting World.

- If you have specific requests, we are happy to give advice on site.

- We look at the bigger picture and offer you comprehensive solutions to problems.

- You can count on our 24-hour service.

One call is all it takes, and we’ll send help within a day. - We will train you and your employees. Be it in software, cutting applications, or pump service .

Perndorfer – A Family-Run Company

Your committed partner for the highest quality.

Everything great once started out small. This is also true of Perndorfer Maschinenbau, which developed from a one-man metalworker shop founded in 1985 into one of the most innovative production operations for waterjet cutting machines and special machines.

The values for which company owner Franz Perndorfer and his team stand have remained the same: reliability, innovative spirit, flexibility, highest quality, and the desire to find a solution to any problem.

As a result, the company has a diversified product range that includes:

- Standard machines

- Prototype construction

- Comprehensive solutions

- Bespoke Machines (Special Machines)

- Trainings

- Specific advice on site

- 24-hour service

Trust in Perndorfer.

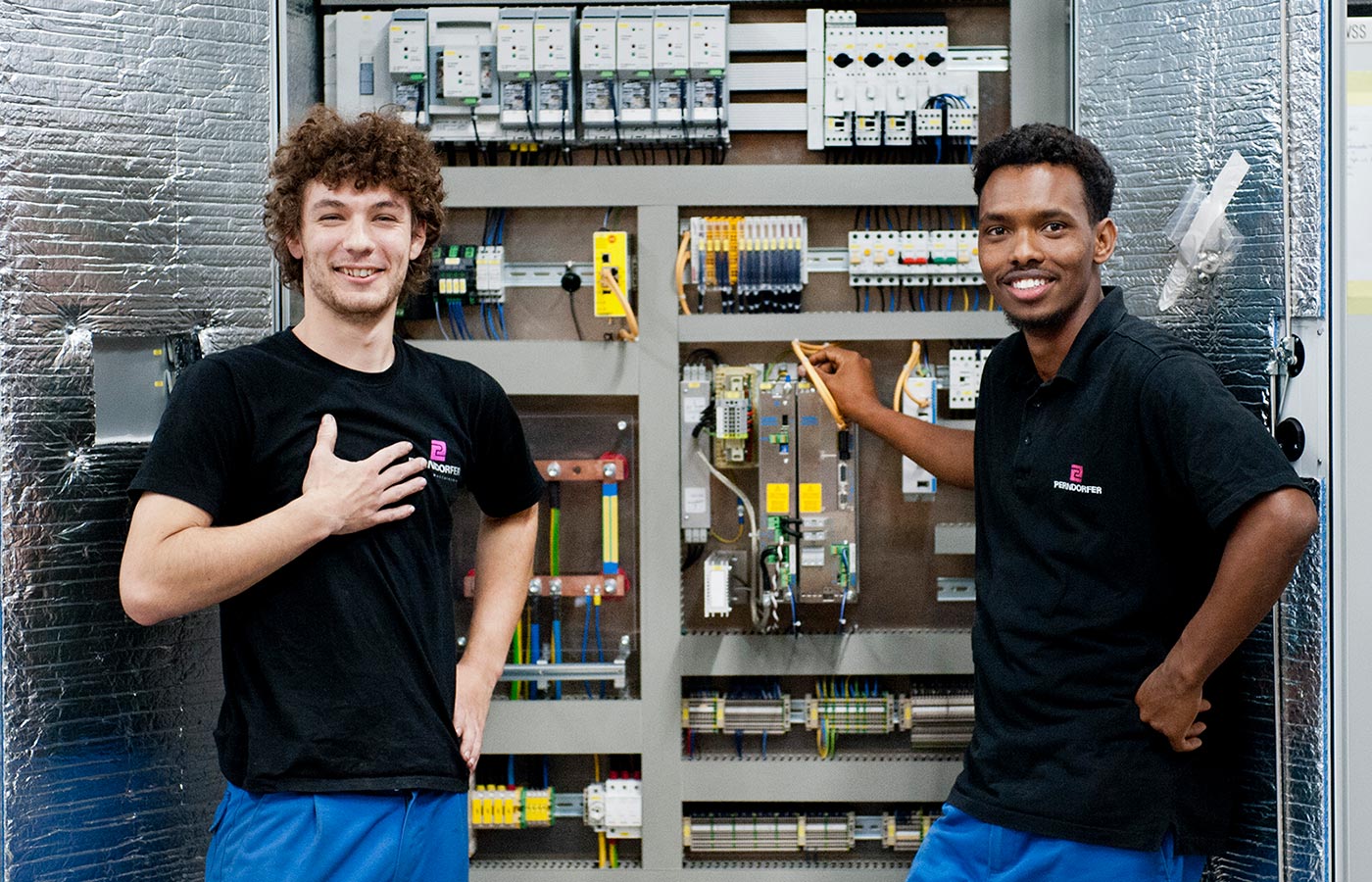

The familiar atmosphere in the whole team is reflected in its commitment. As a dynamic company that acts with foresight Perndorfer offers its team – be it in the office in the factories – the option to develop themselves further. We know that our success is based on our qualified employees.

The familiar atmosphere in the whole team is reflected in its commitment. As a dynamic company that acts with foresight Perndorfer offers its team – be it in the office in the factories – the option to develop themselves further. We know that our success is based on our qualified employees.

Our Success Story:

2019

Ground-breaking for the construction of Perndorfer’s demonstration centre Cutting World. Production area expanded by 500 m² at the Kallham location. Starting in 2020, innovation is going to be top priority at the Cutting World.

2014/15

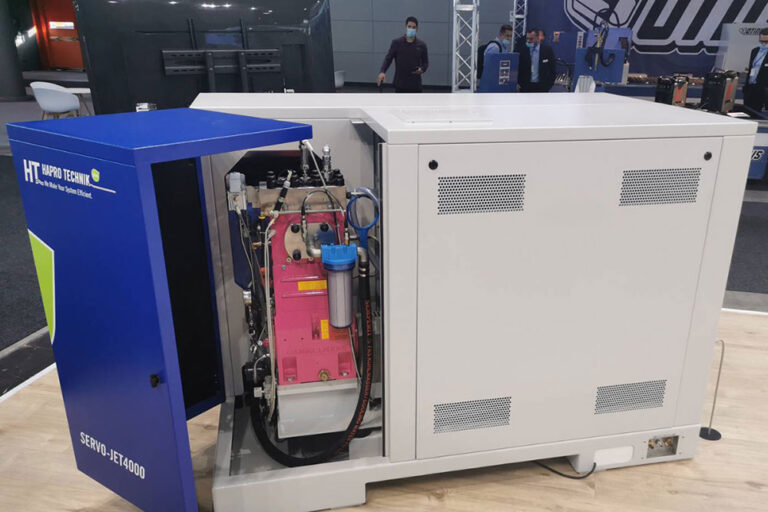

Development, production, and presentation of probably the most energy-saving and most efficient pump in the world, the Servo-Jet4000.

2013

New design and enhanced technology for the WJC machines.

This year at the “Schweißen und Schneiden” trade fair in Essen Perndorfer presents the new electronic beam cutting technology (ESS) which is the result of three years of research and development work in cooperation with the Leibnitz University Hannover.

2006

Development and production of the first tube cutting machine that uses waterjet.

2005/06

Company name change: The individual company Franz Perndorfer becomes Perndorfer Maschinenbau KG and is given a new corporate identity. The corporate slogan “Your committed partner for the highest quality” is coined. But this guiding principle has been followed since the company was founded. It is important for us to manufacture solid and high-quality products with commitment and dedication.

2000

Production area in Kallham expanded by 1,500 m2.

1993

Perndorfer presents its waterjet cutting machines at the “Intertool” trade fair in Vienna.

1991

Construction of the first waterjet cutting machine.

1985

Company foundation. In the one-man metalworker shop the first special machine, an ECG electrode production machine, was made in 1986 one year after the founding.

Sign up for the newsletter

Your personal information will not be shared with third parties! You can unsubscribe from the Newsletter at any time. You will find more information in our Data Privacy Policy

Trade Fair Dates

BlechExpo Stuttgart

07. – 10.11.2023

We look forward to seeing you at the 16th International Trade Fair for Sheet Metal Working (Stuttgart Exhibition Centre)

visit. Hall: 9 / Booth: 9407

Thank you for visiting our stand – it was a pleasure!

Do you need further Information?

Just call us!

We will keep you informed about our participation here!

News & Events

Here we keep you up to date and inform you about news and events of our company.

Newsfeed

Berufserlebnistag 2022

Am Donnerstag, den 13. Oktober 2022, von 16.00 bis 19.00 Uhr in der Sportarena Grieskirchen

Wir sind wieder als regionaler Lehrbetrieb dabei und bieten Einblicke in die Berufswelt! Wir stellen unseren Betrieb vor und informieren über Lehrstellen- und Jobangebote.

Wir freuen uns auf dich (gern auch in Begleitung der Eltern)!

Professional experience day 2022

Upper Austrian Job Week at Perndorfer

On Wednesday, March 30th, 2022 we warmly welcome everyone,

who are looking for a good apprenticeship or job.

Focus: “Apprenticeship at Perndorfer” from 2-4 p.m

Focus: “Career at Perndorfer” from 4.00 – 6.00 p.m

On Thursday, March 31st, 2022 from 9.00 a.m. to 11.30 a.m. we look forward to welcoming interested students.

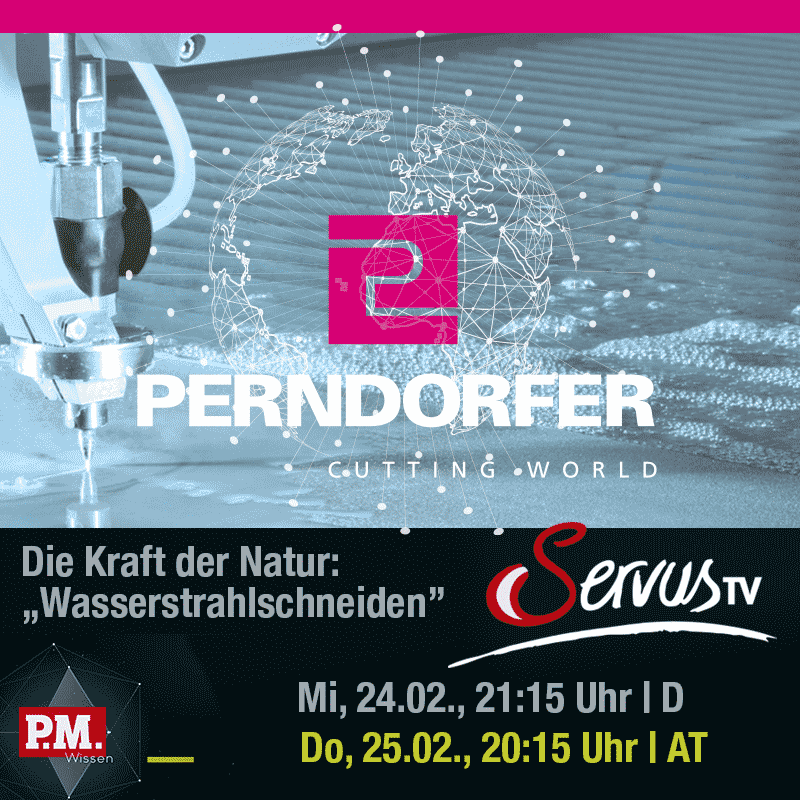

Perndorfer on TV!

Perndorfer-Cutting-World

Our new demonstration and training centre right in Kallham makes waterjet cutting come alive on 220 m2:

- Nehmen Sie an Schulungen und Workshops teil.

- Überzeugen Sie sich von den neuesten Perndorfer Technologien mit der Hochdruck-Peripherie von Hapro Technik.

- Lassen Sie Testschnitte durchführen.