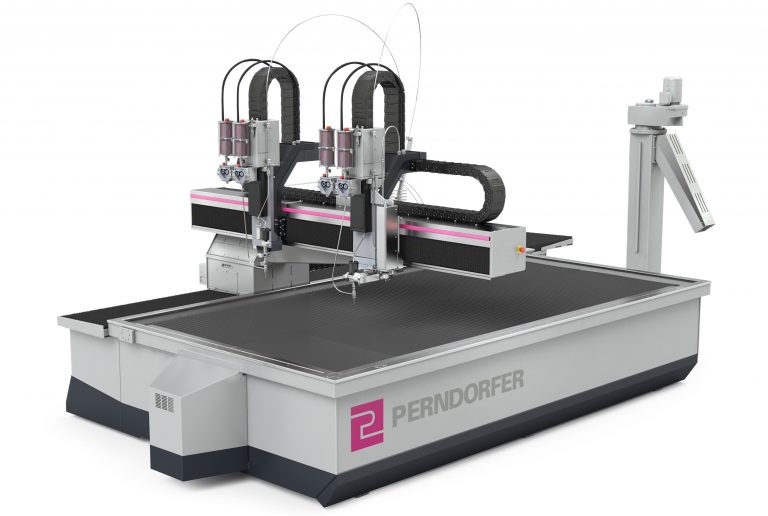

Start » WJC Cantilever

Perndorfer waterjet cutting machines with a cantilever design win over because the cutting basin can be accessed easily from several sides making it possible to load the machine quickly.

The cantilever is constructed and calculated using the latest CAD and FEM technology. A huge welded steel construction guarantees the highest level of stiffness. Up to a working width of 2,500 mm there are no disadvantages compared to the gantry design – we guarantee that with our good name.

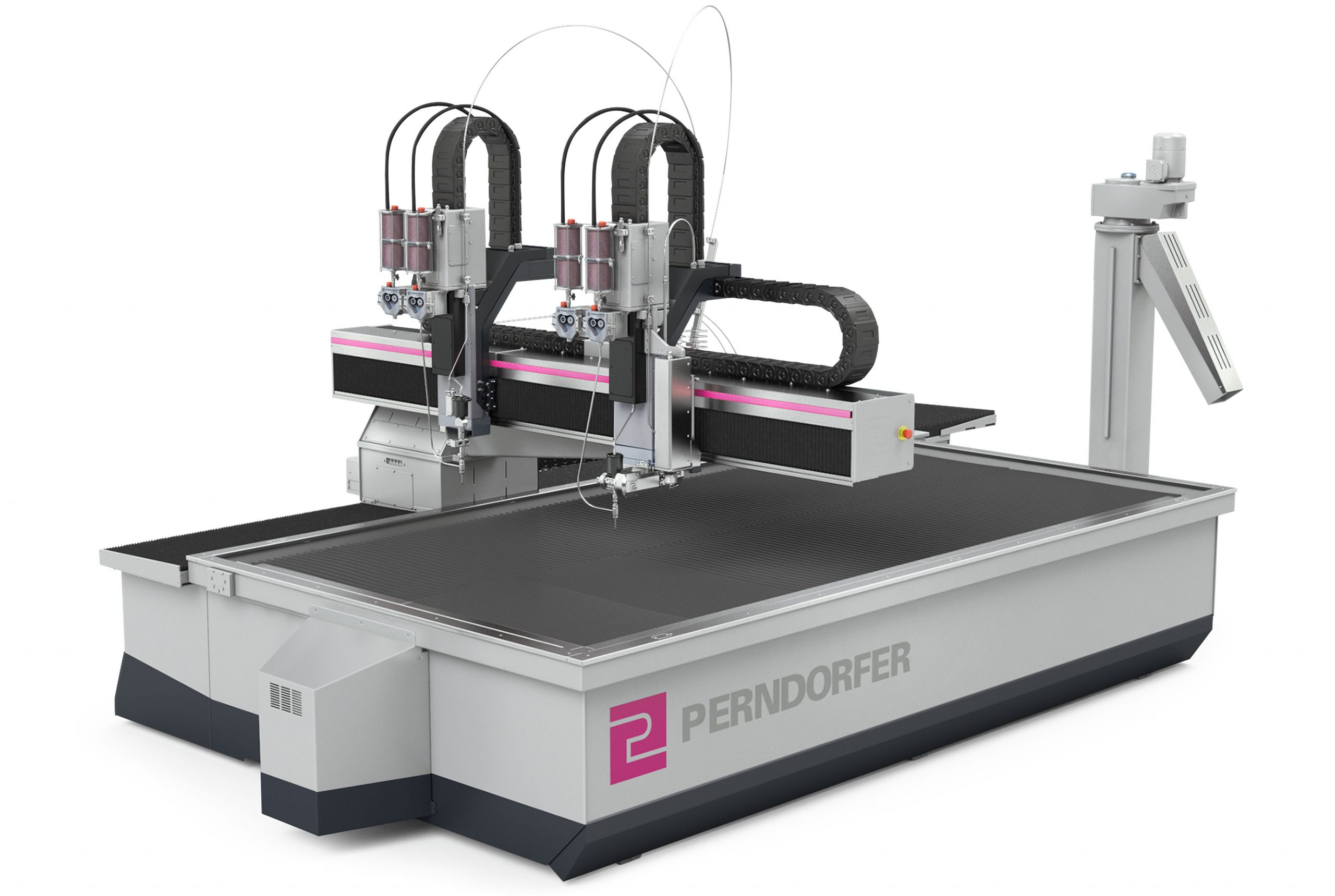

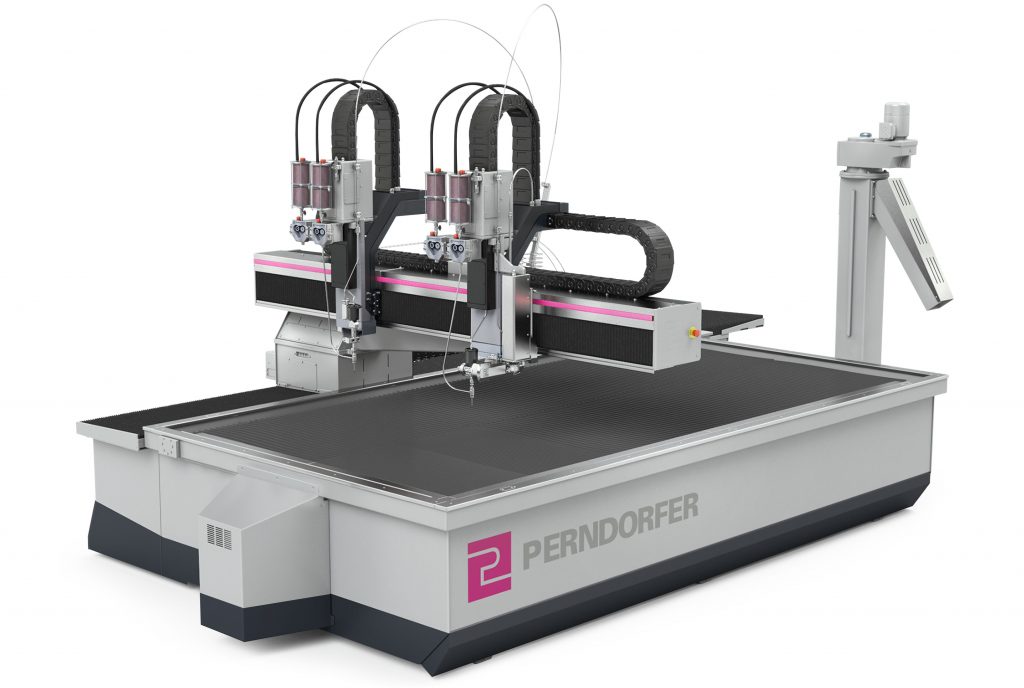

The latest generation of Perndorfer’s waterjet cutting technology. As with the previous generation of machines, the HE series also offers countless options like diagonal cut compensation, a drilling unit, a water level regulator, rotational axis for pipes, and many others.

WJCHE Cantilever

The WJC cantilever is equipped for a wide range of tasks and will work reliably every single day be it during one shift or multiple shifts. Perndorfer’s WJC machines win over with functional construction, sophisticated technology, and a clear-cut design. When working with compact measurements it works at full capacity and is therefore also suitable if space is limited.

Cantilever design (accessible from three sides)

Working surface: 1,000 x 1,000 mm – 12,000 x 2,000 mm

Other sizes available upon request.

The cantilever is constructed and calculated using the latest CAD and FEM technology. A huge welded steel construction guarantees the highest level of stiffness.

Up to a working width of 2,500 mm there are no disadvantages compared to the gantry design – we guarantee that with our good name. Even in the case of machines with more than one cutting head the entire working area can be covered with the main cutting head.

WJCHE Cantilever XL

Thanks to the cantilever design the cutting basin can be accessed from all sides. For this the basin is set up for loading and unloading at an ergonomic distance to the machine's longitudinal axis. Without access from all sides the width to work on is 2,500 mm.

Cantilever design XL: 4-sided access or working width of 2,500 mm with accessibility from 3 sides

Working surface

Accessibility from all sides: 4,000 x 2,000 mm – 12,000 x 2,000 mm

Accessibility from three sides: 4,000 x 2,500 mm – 12,000 x 2,500 mm

Other sizes available upon request.

- Perndorfer’s well-liked sludge removal features reliable and low-maintenance sludge removal of the abrasive and sludge.

- The extremely practical zero stop as well as the clamping strip along the entire x axis and the y axis of the cutting table make it possible for the material to be aligned and clamped quickly and reliably.

- Machines with more than one head are designed in such a way that the main cutting head can always go up and down the whole working area.

- The solid construction means stability and utmost precision.

- The user-friendly controls with job management (job queue), real-time display, graphic restart feature, and many more make it easy to use the machine.

- Many components and add-ons like 3D and bevel cutting heads, a drilling unit, and many more as well as peripheral equipment (like the energy-saving high-pressure pump Servo-Jet4000, or various abrasive conveyors) boost the machine’s performance even more.

Perndorfer’s WJC Box is an encapsulated WJC machine which can be loaded both from above as well as from the front – simply, safely, and conveniently.

WJC Box

This was developed to use WJC machines in labs, and development and testing environments where noise and dirt are problematic.

The machine can be equipped with a ± 60° bevel cutting head.

There is even room for sludge removal! Waterjet cutting is clean, quiet, and completely safe.

Useable up to a working surface of: 2,500 x 1,500 mm