Start » WJC Peripheral Equipment

WJC Peripheral Equipment

Can also be fitted to other manufacturers of waterjet cutting machines!

HD Pump HT-ServoJet4000

Developed and patented by Perndorfer

Water Recycling System HT-RS

Developed and patented by Perndorfer

Abrasive Container HT-AF-Gravity

Developed by Perndorfer

HD Pump HT-ServoJet4000

With its amazing energy efficiency and simultaneous high cutting speed the Servo-Jet4000 has hands down the highest penetrating power.

The 3-piston plunger pump stands out with large flow volumes (8.4 l) extremely low power consumption (55 KW) and thanks to Servo technology is probably the most efficient high-pressure pump in the world!

Developed and patented by Perndorfer.

Pump Models: SJ30, SJ55, SJ30 Pure, SJ55 Pure, SJ 18

The SJ 18 impresses with an economical 32 A connected load.

For WJC RW Pure Water Machines the “Servo-Jet4000 Pure” with near record-breaking switching cycles is recommended.

Also included in the product portfolio are high-pressure pumps based on the principle of a pressure intensifier with a motor capacity of 10 to 90 kW and a pressure of up to 6,200 bar.

- High energy efficiency: various funding can be applied for

- High efficiency: directly powered pump, no pressure intensification with hydraulic oil

- Servo drive – no blind current

- High litre output for higher cutting speed compared to equivalent pumps

- Continual readjustment of the cutting pressure on the set value – compensation for various signs of wear like nozzles, etc.

- Integrated pulsation damper: constant waterjet and minimal material wear (HD lines, etc.)

- Complete unit with sound hood

- Save money and conserves the environment

Water Recycling System HT-RS

Perndorfer’s patented water recycling machine helps save water. It is easy to integrate into existing machines, requires little energy and freshwater, and is easy to use. Noteworthy is that the water recycling system operates entirely without the addition of chemical additives and is, moreover, easy to operate. The filter elements are almost wear-free. The result is a closed water recirculation where no wastewater enters the sewer system.

• Independent of manufacturer and self-sufficient, for that reason easy integration into existing machines

• for that reason easy integration into existing machines

• Very low maintenance

• No wastewater enters the sewer system,

• therefore independent of official requirements

• Can be used in many applications (water treatment plants, industrial water treatment plants etc.)

• Treats water that contains abrasive particles without chemical additives

Water Purifier HT-PR Evo2

Increase the service life by reducing silicate and improving water values without adding chemicals!

Optimal water quality for use in high-pressure pumps

• protects sensitive high-pressure technology from all kinds of dirt

• reduces wear and maintenance costs

Instead of more expensive technology, the Preparing System HT PR-EVO2 enhances all the factors of water quality that can reduce service life with intelligent, effective materials without adding chemicals.

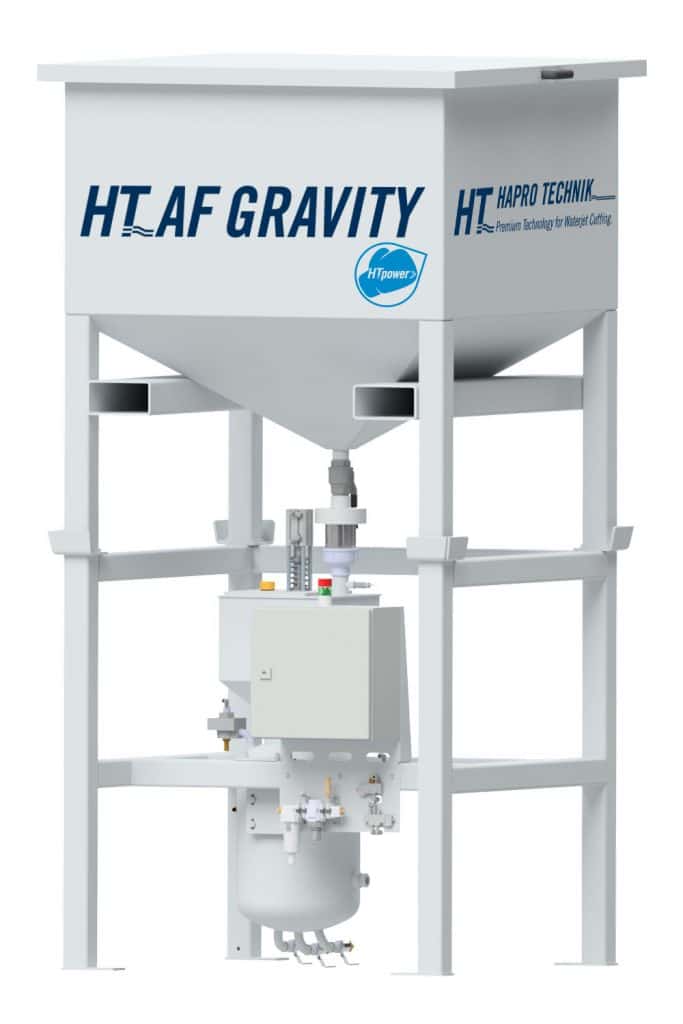

Automatic Abrasive Conveyor HT-AF Gravity

Perndorfer develops and manufactures the automated abrasive conveyor

HT AF Gravity, which can be filled with a minimum of two tonnes of abrasive.

Sensors monitor the level of abrasive in the containers, a warning light shows the level of the abrasive conveyor and signals in good time if more abrasive is needed.

The abrasive container can be filled without releasing the pressure in the system.

Measurements: H: 2,600 mm x W: 1,300 mm x D: 1,300 mm

Filled with: 1 Mt or 2 Mt big bag

Filling capacity: max. 2 t

Empty weight: 510 kg

Operates with up to 4 cutting heads – max. 100 kg/h

Automatic Abrasive Conveyor HT-AF Hoover

With the automatic abrasive conveyor HT-AF Hoover, the loose abrasive big bag is positioned beside the abrasive conveyor.

The abrasive conveyor removes abrasive with a suction lance from the big bag and fills its container. The suction is continually monitored.

There is no need to fill the pressure container by hand or lift heavy sacks full of abrasive.

A warning light shows the level, and the washable dust filter bag makes maintenance easy.

Measurements: 2,100 mm x W: 610 mm x D: 850 mm

Filled with: 1 Mt or 2 Mt big bag

Filling capacity: max. 2 t

Empty weight:500 kg

Operates with up to 4 cutting heads - max. 100 kg/h

Abrasive Container HT-AF Standard 200 l

This abrasive container is usually filled with sacks and used with waterjet cutting machines with one cutting head or as a second container for an alternative abrasive grain.

Measurements: 1,400 mm x W: 850 mm x D: 850 mm

Filled with: 25 kg sacks

Filling capacity: max. 400 kg

Empty weight:200 kg

Operates with: 1 cutting head – max. 25 kg/h