Start » WJC Special Machines

Efficient machines for special products – bespoke solutions for clients with special requirements.

Exceptional Waterjet Cutting Machines.

Since 1986, Perndorfer Maschinenbau KG has been making bespoke machines that enjoy an excellent reputation in various sectors. Added to this expertise is knowledge accumulated from decades of designing and manufacturing waterjet cutting machines. This makes us one of the few manufacturers of high-quality, special waterjet cutting machines that can be tailored exactly to client requirements. We gladly rise to difficult challenges!

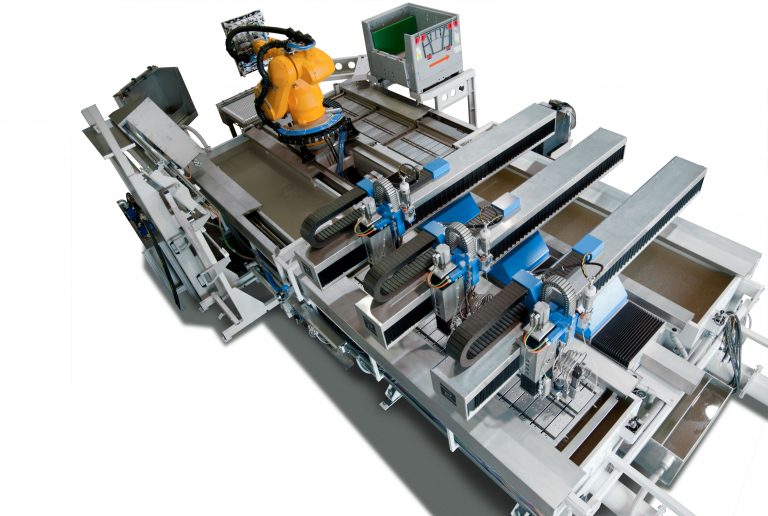

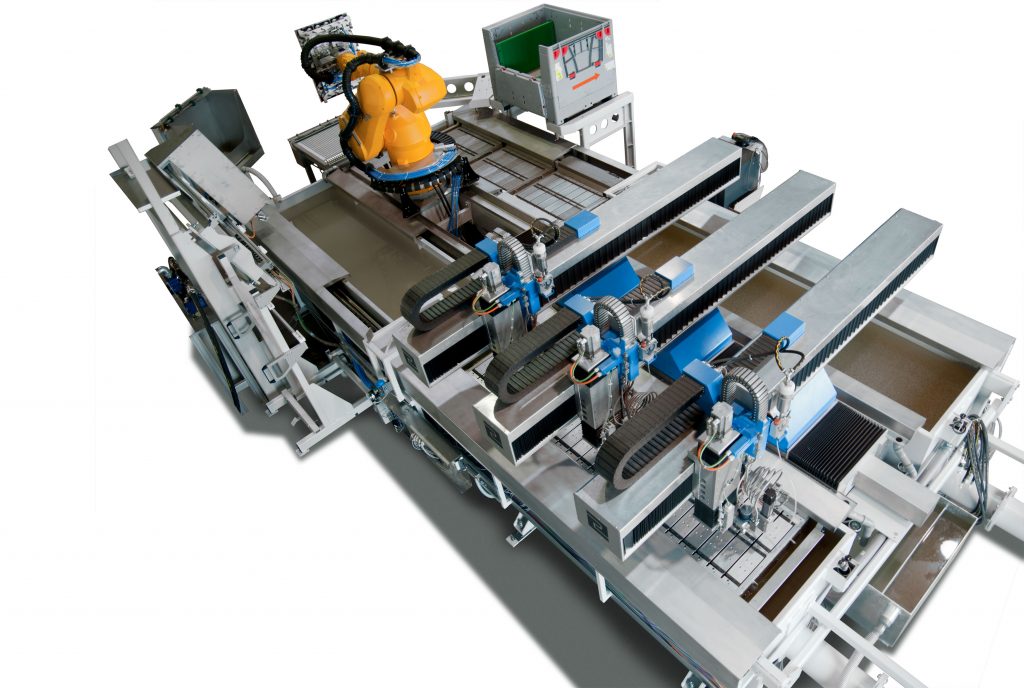

Display Machine

(Bespoke client solution)

Fully automated 15-axis waterjet cutting machine to produce display glass for the automotive industry

Key features:

• Three 5-axis cutting heads with abrasive dosing

• 2 auxiliary axes to adjust the cutting table

• 2 individual cutting basins (with automated water regulator)

•Optical measuring component

• 5-axis articulated arm robot for component handling

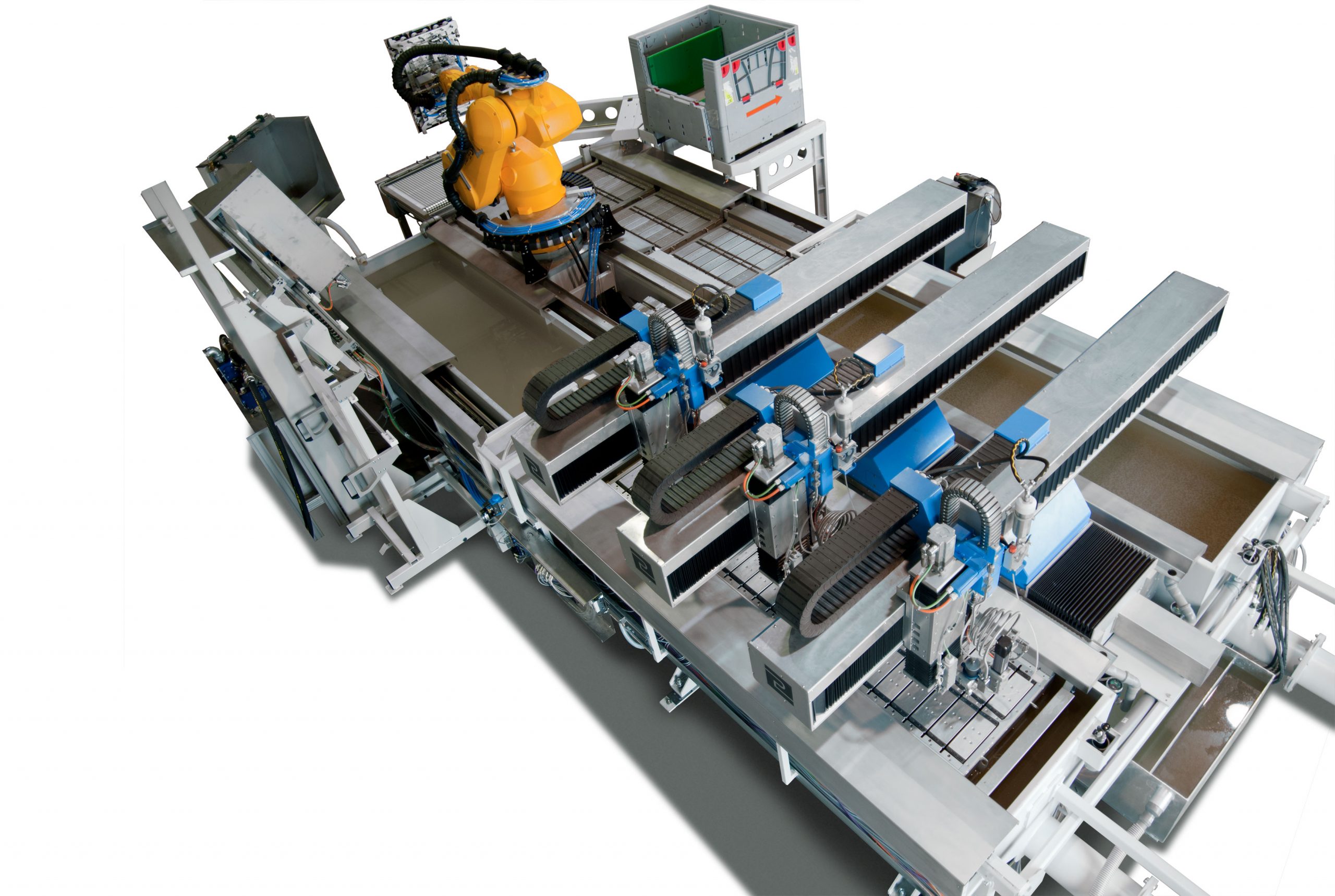

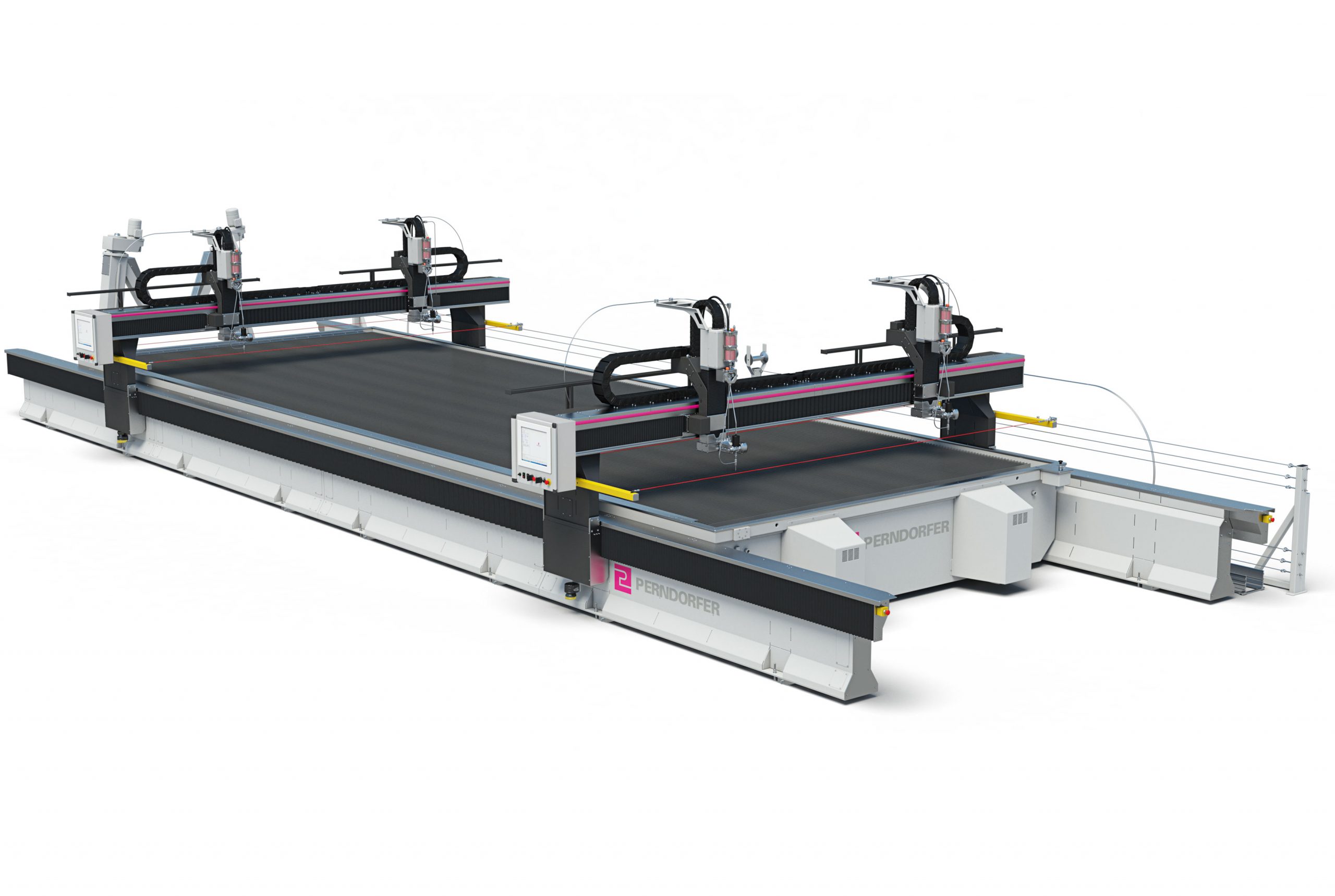

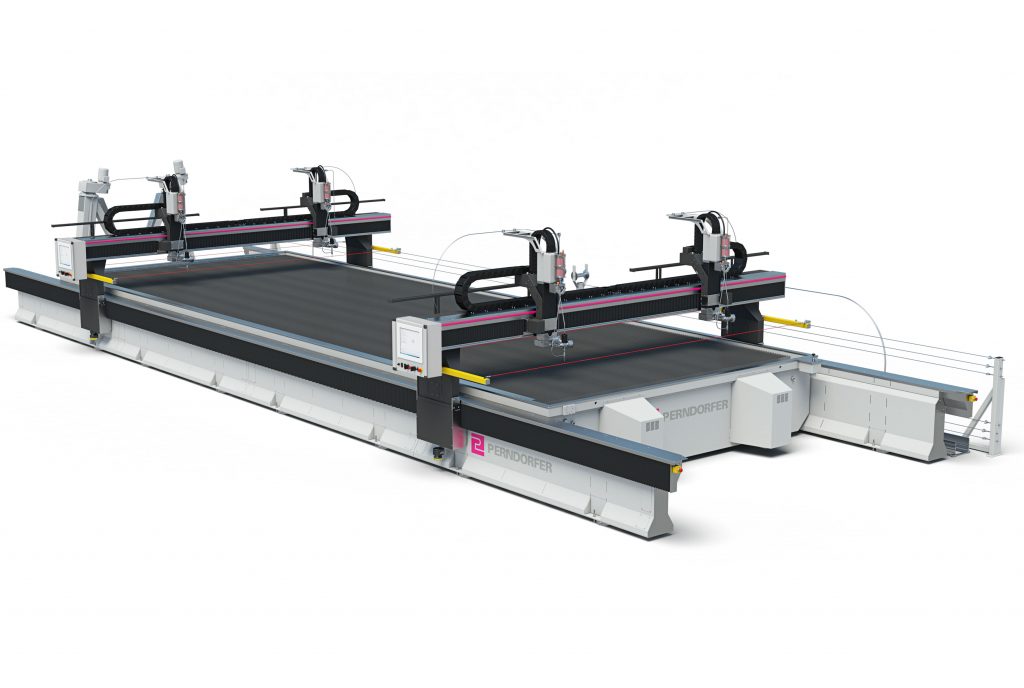

WJC HE Double Gantry

(Bespoke client solution)

• Cutting basin with a working surface 12,000 x 4,000 mm

• Two gantries that work independently

• One gantry can work up and down the entire working surface of 12,000 x 4,000 mm.

• Dual Perndorfer sludge removal

• Four 5-axis cutting heads

• Upon request the control panels are affixed to the gantry.

Working surface: 12,000 x 4,000 mm

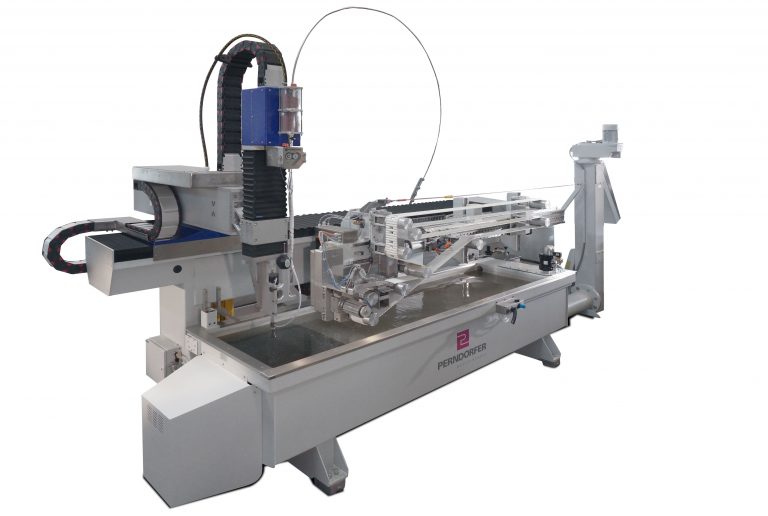

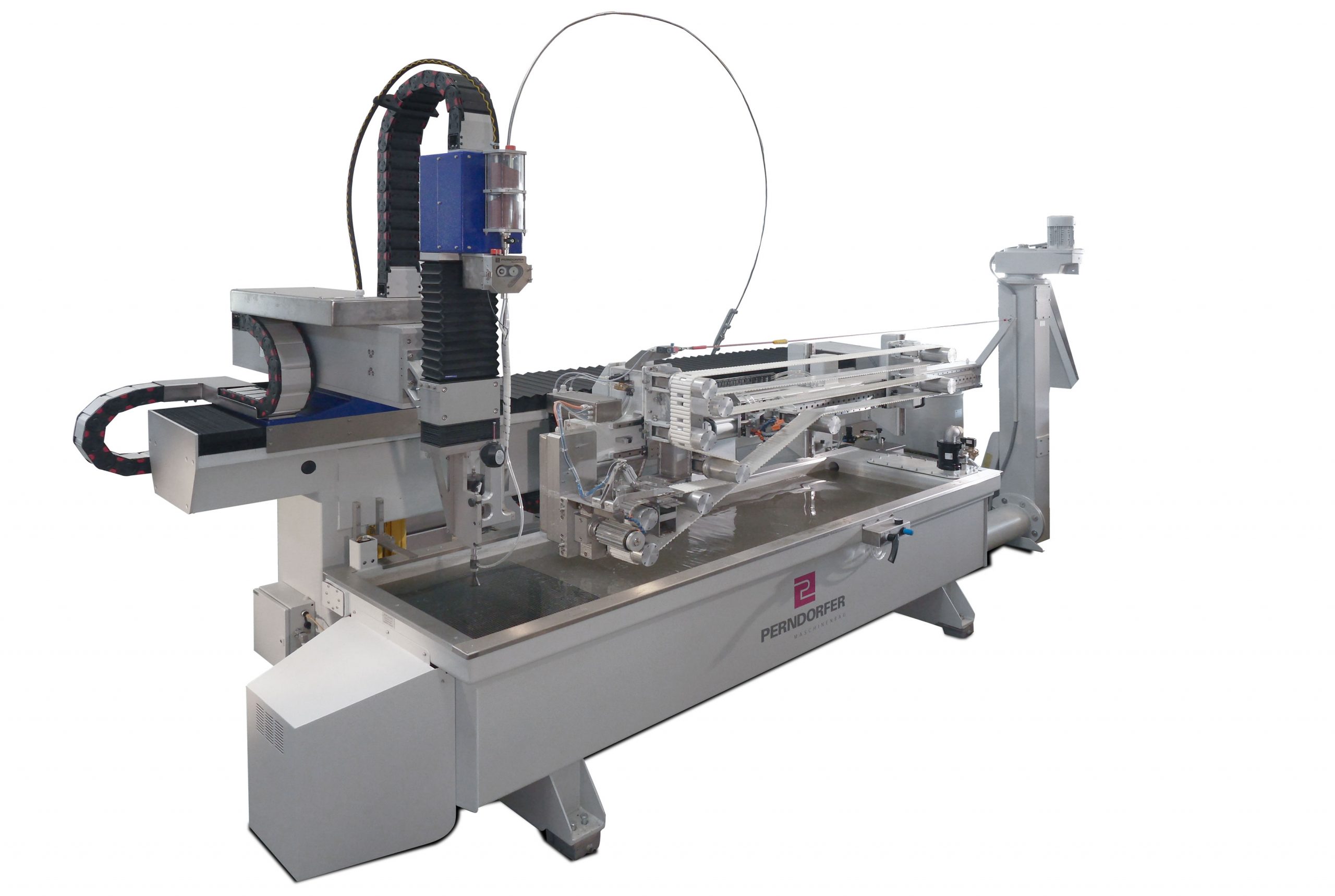

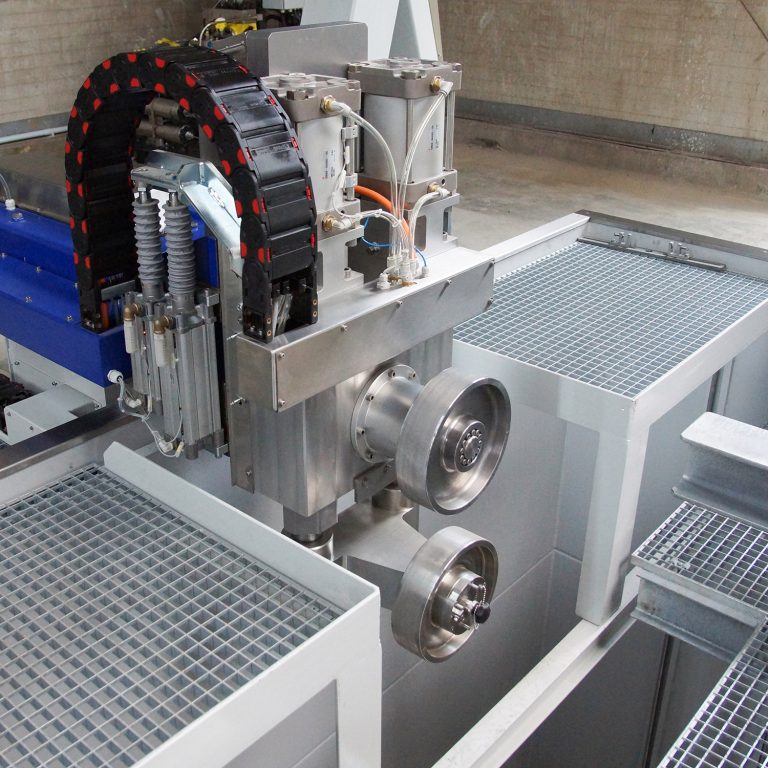

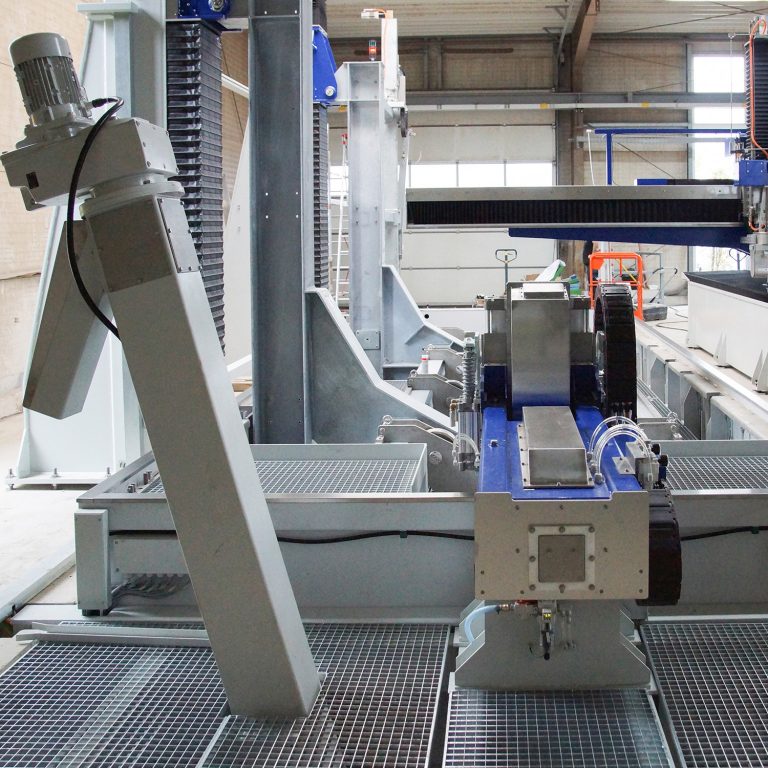

WJC for Toothed Belts

(Bespoke client solution)

Special waterjet cutting machine to cut toothed belts measuring 1,000 to 14,000 mm in length and different modules.

Key features:

• Small flatbed area

• Lifting unit for convenient setup above water

and cutting below water

• Belt rinsing

• The software was tailored exactly to the requirements, like with all special waterjet cutting machines.

This way the machine is easy to use, efficient, and complies with the application purpose.

Device for processing toothed belts in detail.

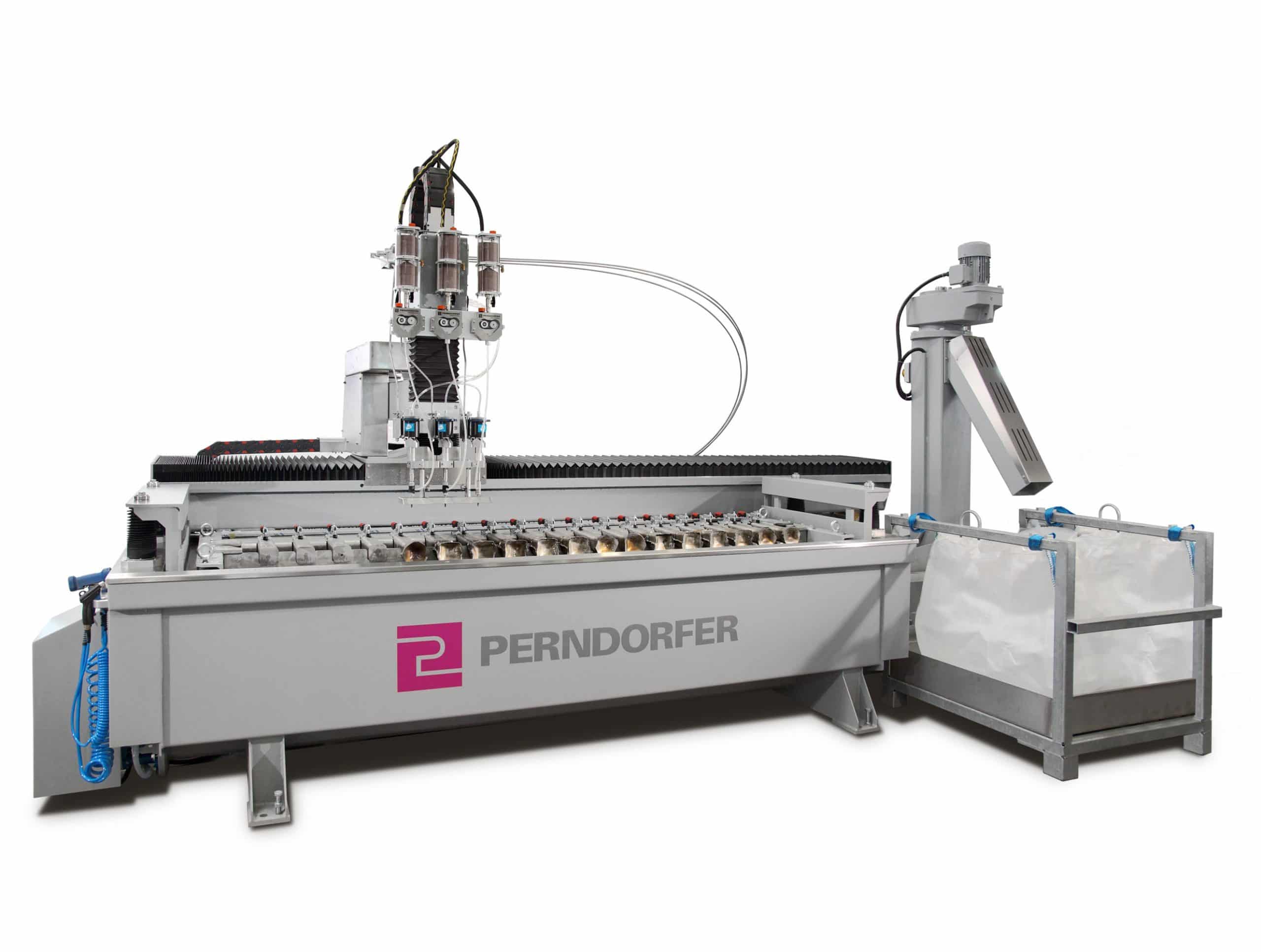

WJC for Cast blanks

(Bespoke client solution)

2-axis special WJC machine for cutting off cast blanks.

Key features:

• Changeable cutting device with clamp and holder for up to 18 cast blanks

• Lift tables for cutting under water and setup above water

• Perndorfer Sludge removal (screw conveyor)

• A HD Pump HT-ServoJet4000 (SJ55) enables

• 3 Cutting heads with water nozzle, each with a cutting jet diameter of 0.3 mm

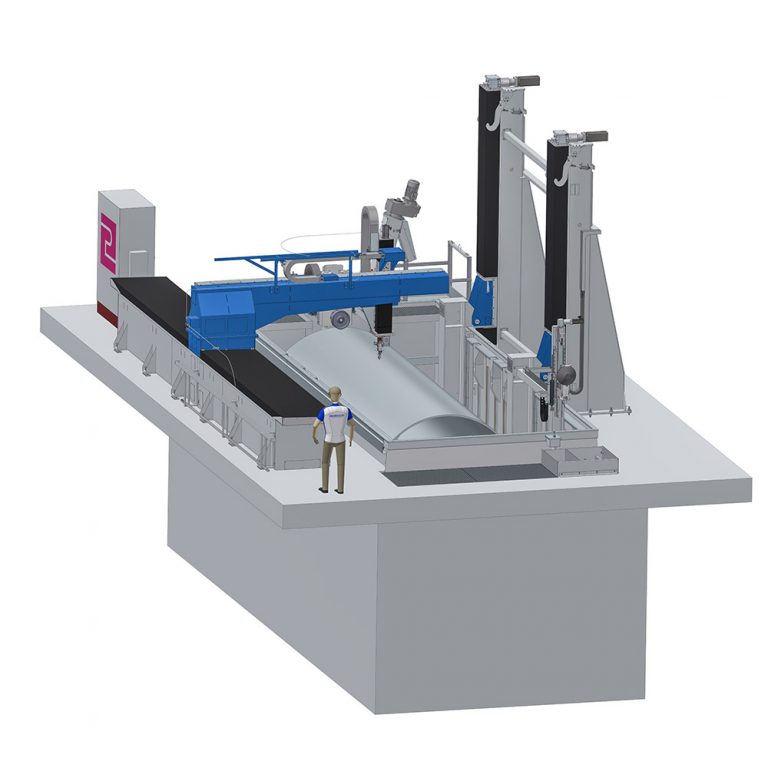

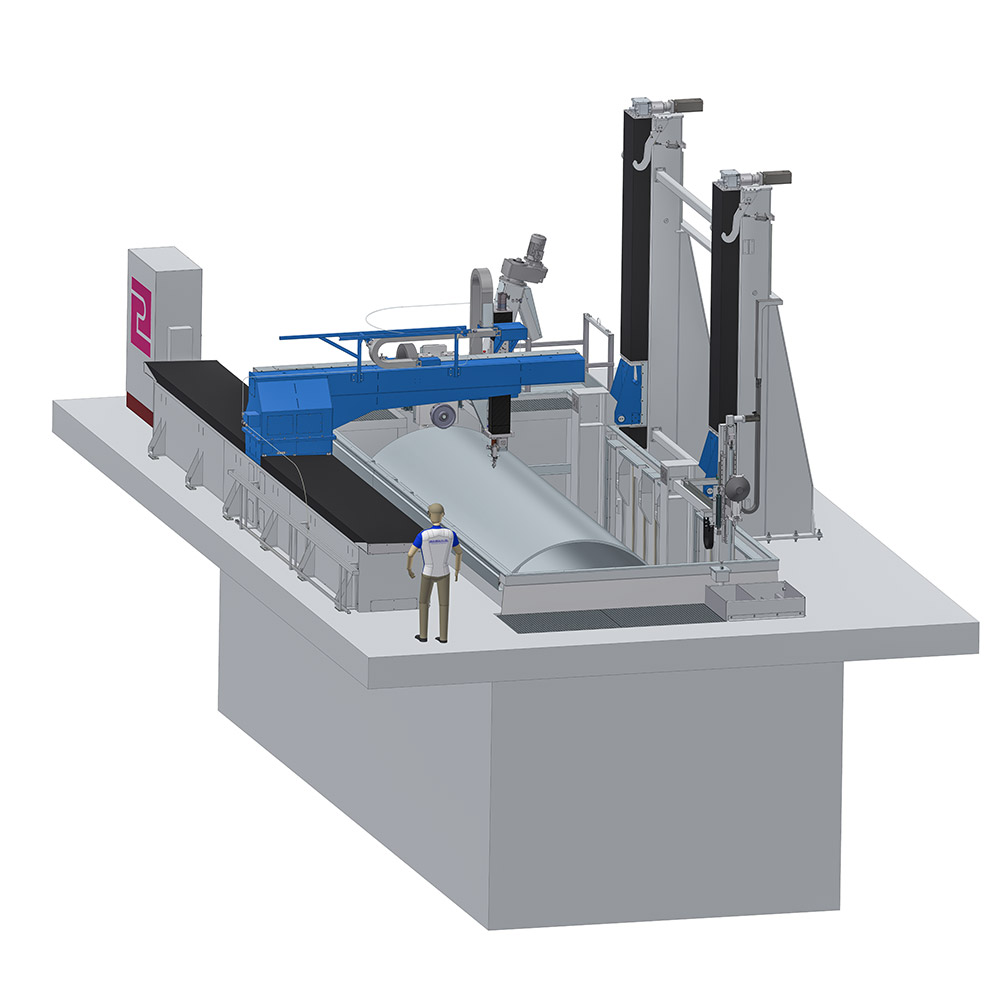

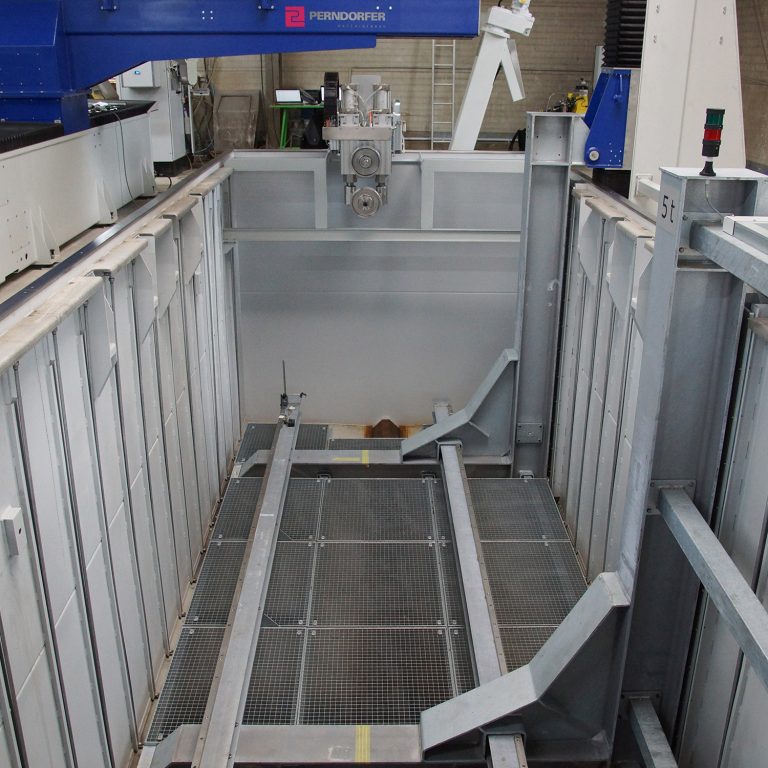

WJC Tube 2500/6000

(Bespoke client solution)

WJC custom system to cut tubes, Klopper heads, and flat materials.

Key features:

• Cantilever XL and full 3D cutting head

• Cutting basin 9,000 x 3,500 x 3,500 mm, embedded into the bottom

• Lifting towers for setup above water and to cut tubes under water for tubes D =150 to 2,500 mm; L = up to 6,000 mm; H = up to 10 t

• Automatic drift compensation

• • Flatbed area to cut sheet material 3,000 x 2,000 x 600 mm

• • Cutting Klopper heads with a diameter of up to 2,000 mm

WJC for Brick Walls

(Bespoke client solution)

With this system, walls can be cut and the necessary recesses for electrical outlets and cables can be cut out perfectly. Because the cutting process takes place on a vertical plane, extraordinarily little water penetrates the wall.

The waterjet cutting machine is used in the construction of solid prefabricated houses.

The manufacturers of brick setting machines or brick products are the target group for this system.

Component data – Brick width: 100 to 500 mm

Height of brick wall: up to 3,500 mm

Length of brick wall: up to 12,000 mm

Weight: 20,000 kg

We integrate the waterjet cutting machine into complete production lines and incorporate them perfectly into the safety concept for the entire machine. Communication with the control stand and the automatic transmission of cutting data are clarified in detail in advance and subsequently realised.

We also develop and produce small waterjet cutting machines or waterjet cutting machines with special clamping devices. Moreover, their control system is designed to be especially user-friendly.