Start » WJC Tube

Cutting tubes, shaped tubes, and I-sections also with mitre and bevel cutting, cutting tubes with a diameter of 50 – 4,000 mm and a wide range of materials.

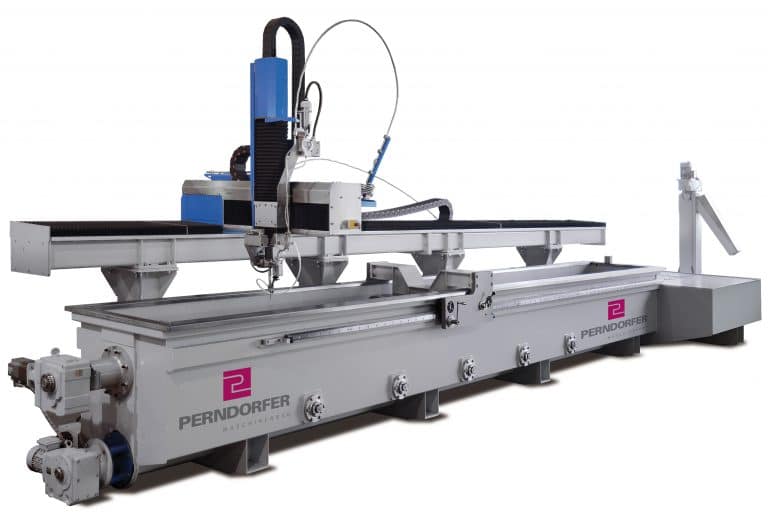

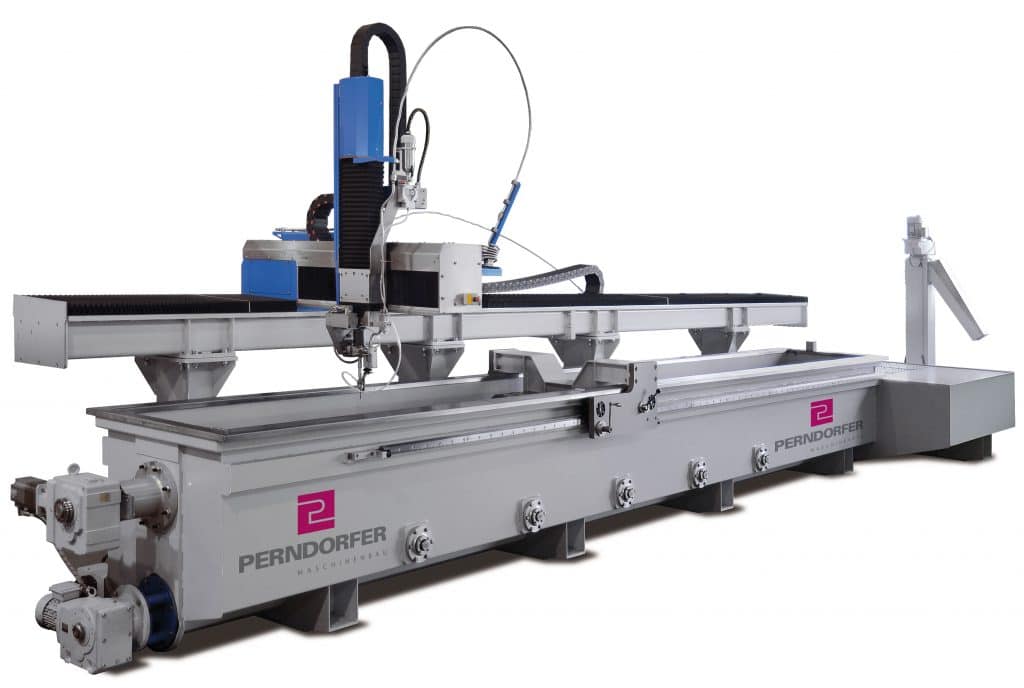

WJC Tube 650/6000

This 6-axis machine has impressive features. The variable clamping head allows for the cutting material to be changed without retooling. Automatically controlled bezels simplify the insertion process and provide support for cutting.

Cutting under water minimises noise and dirt. The remaining energy dissipates from the cutting jet.

Component size: Tubes up to 650 mm ø and 6,000 mm long

Other sizes available upon request.

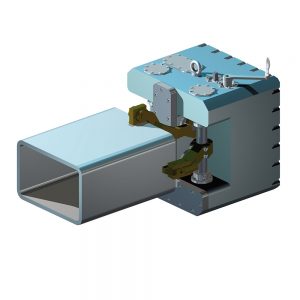

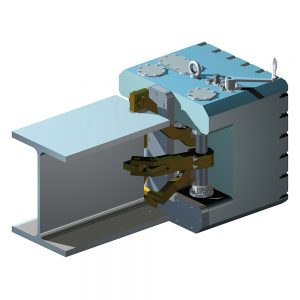

The variable clamping head enables the clamping of tubes, formed tubes, and various profiles (e.g. I-sections) without any time-consuming retooling. As a result, work is guaranteed to be faster and more efficient.

Cutting under water has some important advantages: There is little noise and dirt pollution. The residual energy of the waterjet dissipates and cannot do any harm. Being able to quickly raise or lower the water level is another plus and helps save time.

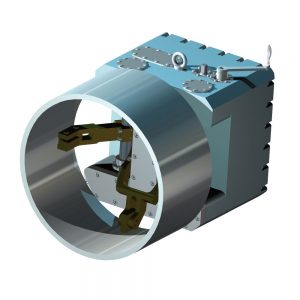

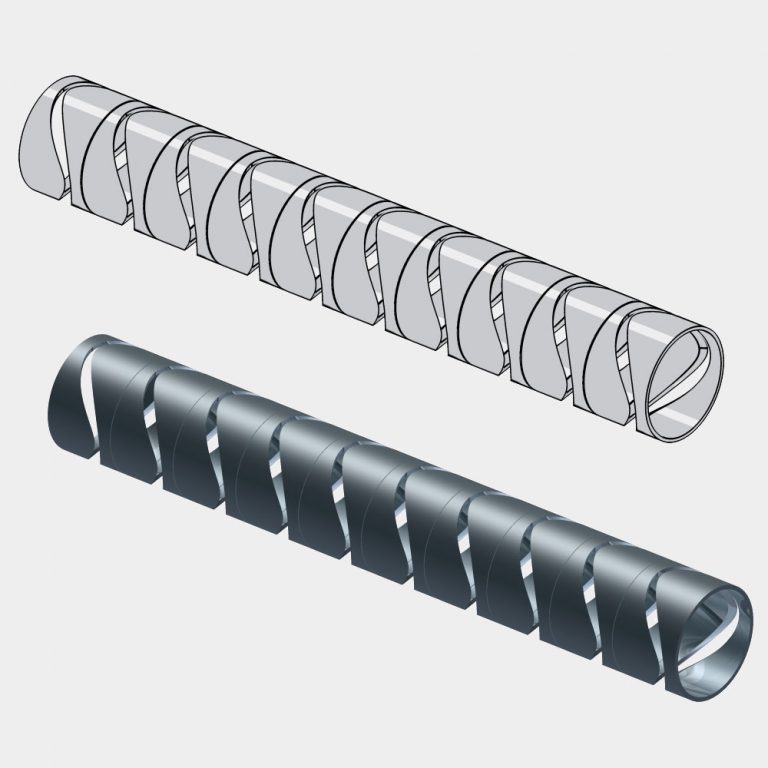

Clamping a tube, a formed tube, or an I-section.

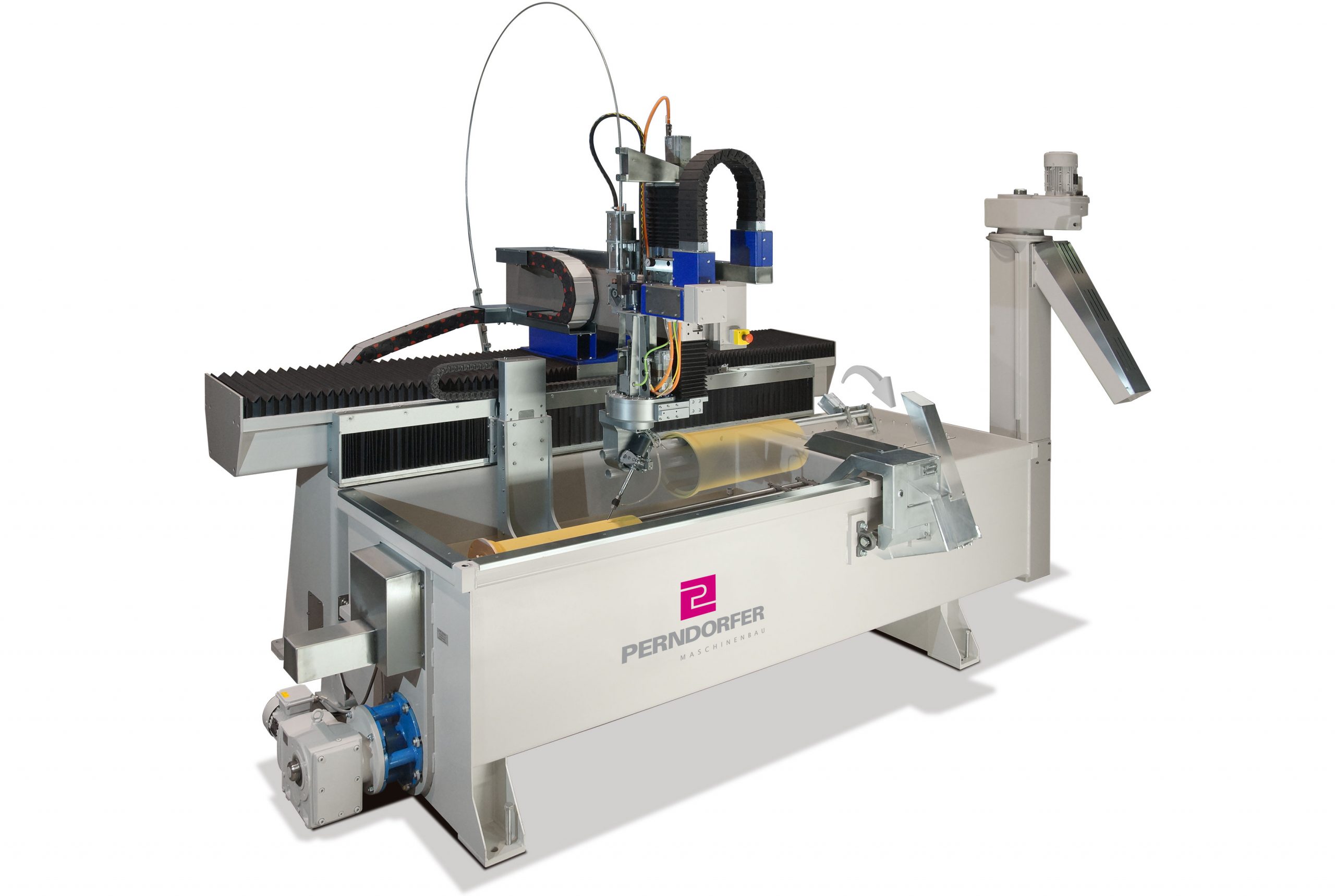

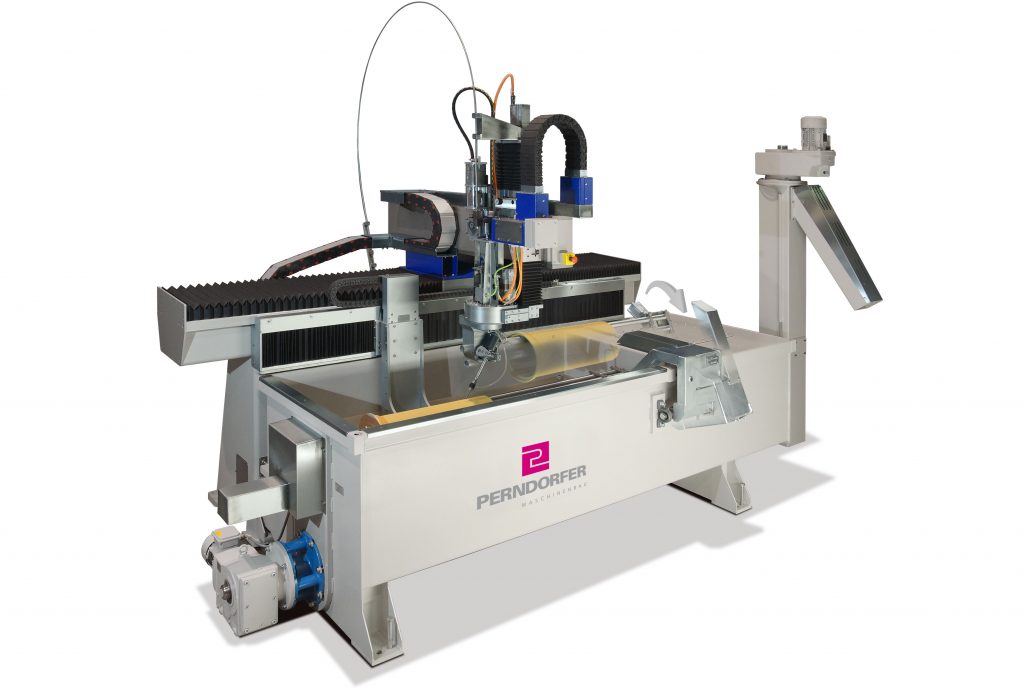

WJC Tube 4000/6000

This is a system for those applications where the inside wall of the tube cannot be damaged in any way.

The incision is made from the inside to the outside which prevents damage, and the immediate area surrounding the working area is hardly affected. Suitable for tubes with a diameter of 500 to 4,000 mm.

On request, the 5-axis system can be equipped with a printer or a marking device.

Component size: Tubes with a diameter from 500 to 4,000 mm

Other sizes available upon request.

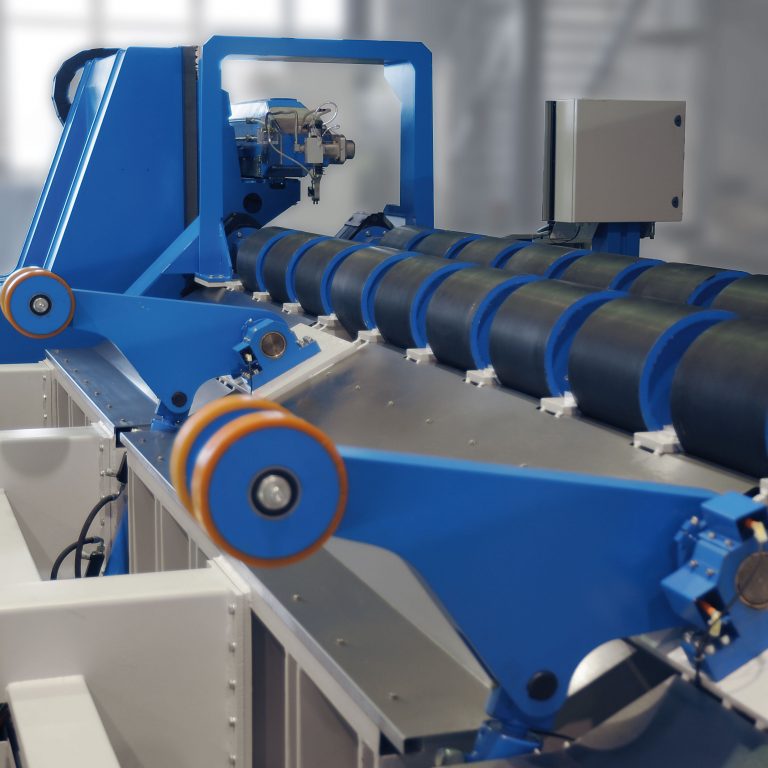

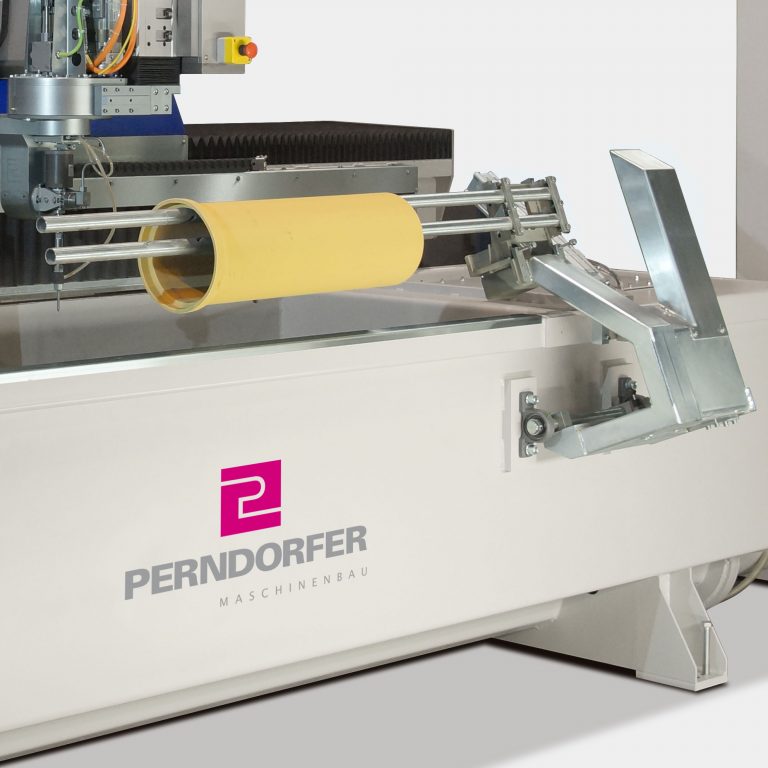

Safe and convenient way to load the machine.

There is the option to fit the system with a printer (inkjet) to automatically label the tubes.

This not only labels tubes, but also applies index or grade markings accurately. This option offers enormous saving potential when it comes to further processing.

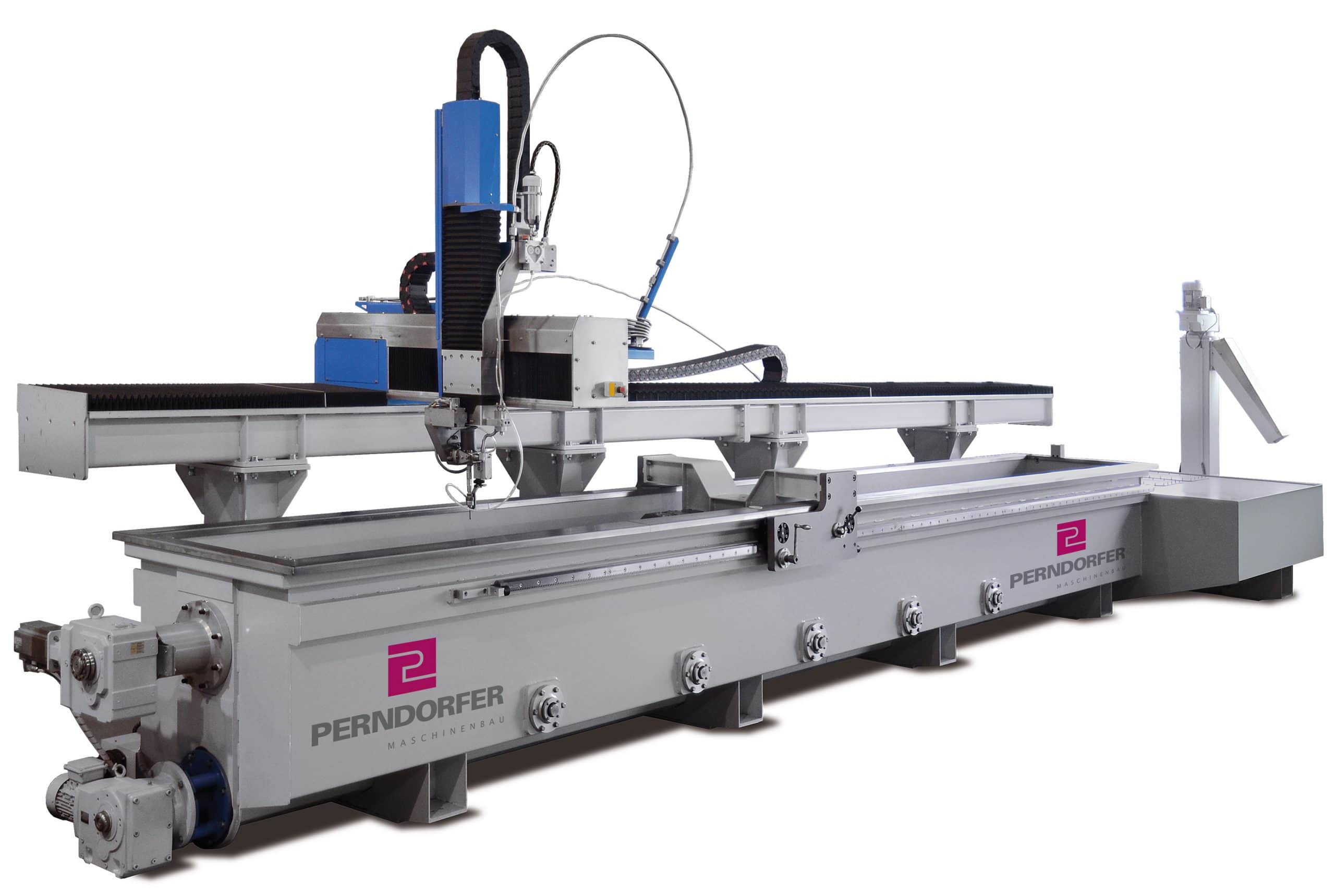

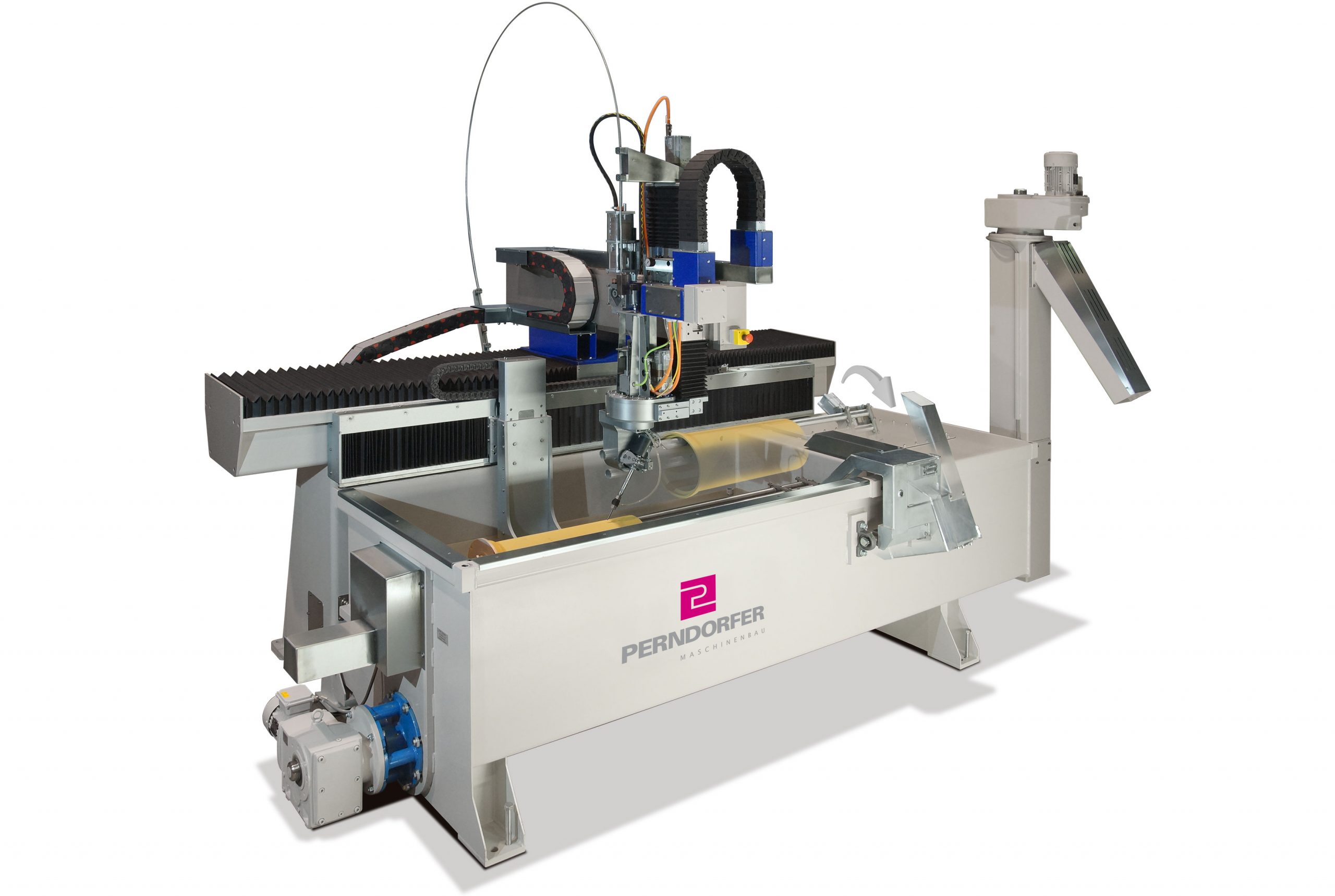

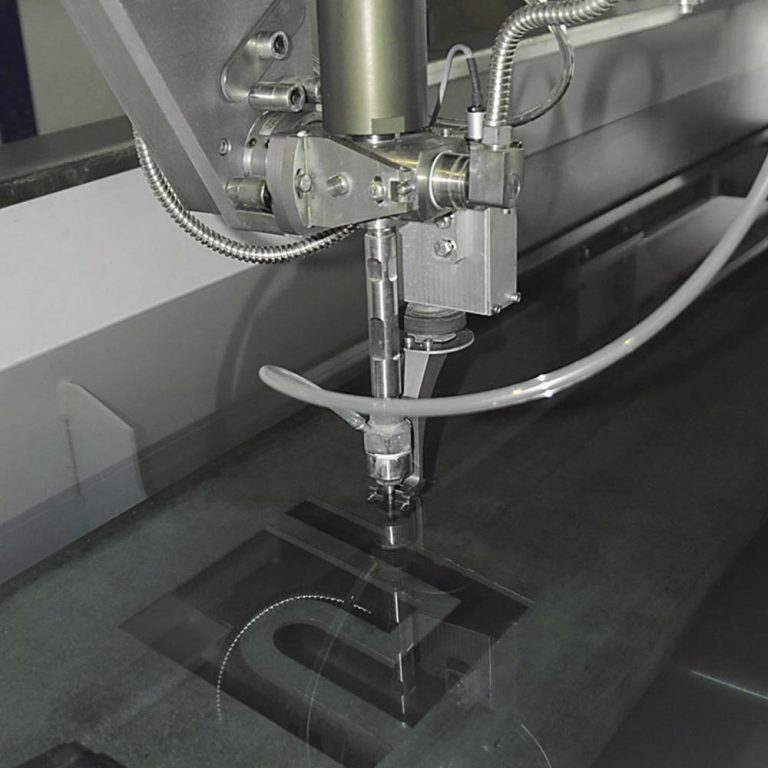

WJC Tube 400/1500

A compact tube cutting machine with a swivel unit for cutting smaller tubes with a diameter of up to 400 mm.

The automatically adjustable tube support makes it possible to cut several tube segments without having to re-clamp.

Model with cutting basin.

(Fig.: Lowered swivel arm in the cutting position)

Component size: Tubes up to 400 mm in diameter

Other sizes available upon request.

The automatically adjustable tube support (w axis) makes it possible to cut several tube segments without losing time for re-clamping. The segments that have already been cut remain in the catcher or can be pushed back with the w axis to avoid colliding with newly cut segments.

The tube cutting machine works precisely and efficiently and ensures the greatest possible yield. It is also suitable for bespoke and standardised series production of tube segments.

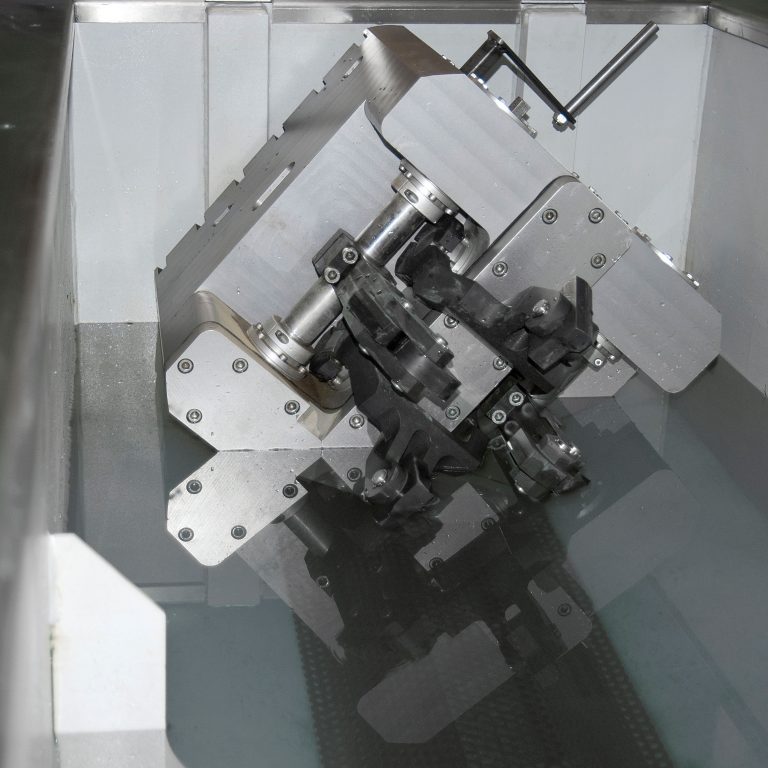

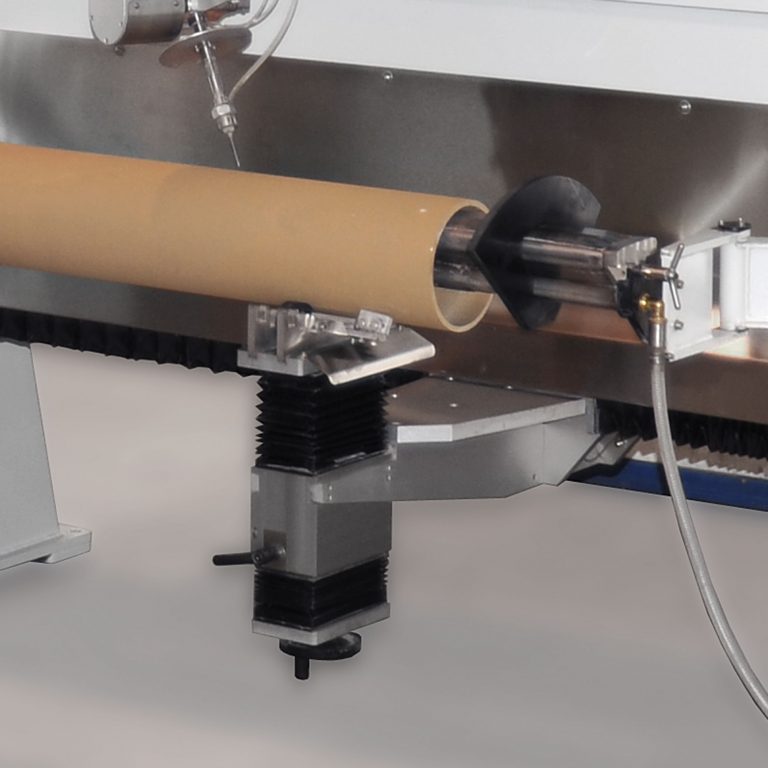

Cutting tubes under water requires a robust clamping chuck that is designed for the harsh environment of the abrasive and water mixture. Perndorfer’s clamping chuck was developed with exactly this application in mind.

The clamping claws cannot get stuck and even after years they run smoothly because the mechanism is situated inside the water-tight chuck. Even machines from other companies can also be retrofitted with Perndorfer’s clamping chuck.

This makes it easy to conveniently load outside of the cutting basin.