Special Machines

Start » Special Machines

Bespoke Solutions

For a range of requirements

Perndorfer Maschinenbau KG’s special machines have an excellent reputation in a variety of sectors. We guarantee excellent service, short response times, and on-time delivery of services.

See the variety we offer first-hand – upon request we offer you:

- Feasibility study

- Construction with the finite element method

- In-house production in mechanics, electrical systems (hardware and software)

- Unit and machine ready for operation, including training, technical documentation, and risk analysis.

We always have the right solution for a variety of requirements.

Maybe the Perndorfer machine you need already exists?

Belt strap production unit for semitrailers

Component measurements:

H: min. 350 mm, max. 3.000 mm 500 mm, max. 1,200 mm

L: min. 5,000 mm, max. 14,000 mm

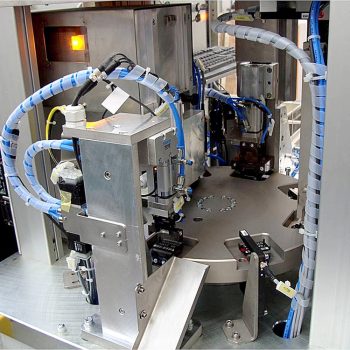

Fully automated production of freezers

Working steps:

- Acquisition of the outer shell

- Integrating the individual components

- Clamping and welding with the laser welding unit (Trumpf)

- Subsequent turning

- Shipment of the freezers

Cycle time ca. 30 seconds

Component measurements:

W: min. 600 mm, max. 1,200 mm 600 mm, max. 1,200 mm

L: min. 1,200 mm, max. 2,400 mm

Top-hat rail machining

Fully automated production of mounting rails in various lengths, with holes, elongated holes, and key holes in a range of designs.

Waste optimisation of different support rail models and jobs.

Warehouse with ca. 200 rails of primary material

Key features:

Punching force: 100 k,

Component production: L: 60 – 3,000 mm

Tool and tooling:

30 fixed punching locations

Materials: steel, copper, stainless steel, and aluminium

Laser marking

Direct labelling on plastic parts,

data matrix or barcode text data, with subsequent check

Cycle time: 700 msec

Special milling machine for series production

Machining area:

W: 1,000 mm, H: 1,300 mm, D: 750 mm

4 machining units simultaneously

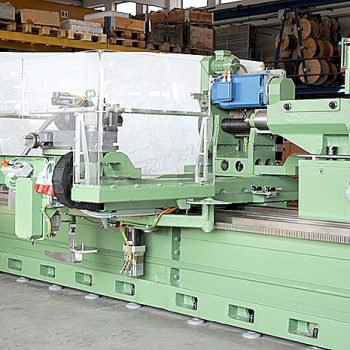

Cylinder machining centre

Production possibilities: rotating, grinding, polishing, grooving

Technical data:

cylinder lengths: 0–6,200 mm

Longest length: 6,500 mm

Diameter Ø: from 0 to 850 over slide

Ultrasonic inspection unit with 10 CNC axes

Testing of “flap track fairings” for Airbus A380

Working areas without gantry model:

X: 8,000 mm, Y1: 2,200 mm, Y2: 2,200 mm, Z1: 2,500 mm, Z2: 2,500 mm

Z1: 2,500 mm, Z2: 2,500 mm

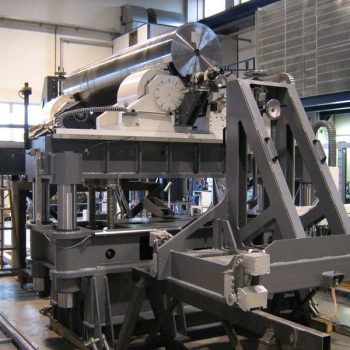

Ultrasonic testing unit for shafts

Working areas for contact technology:

X: 20,000 mm, Y: 2,000 mm, Z: 2,500 mm

For shafts of:

∅: min. 0 mm, max. 50 mm 200 mm, max. 2,200 mm

L: min. 1,700 mm, max. 20,000 mm,

Weight to max. 150 tons

Ultrasonic inspection unit for discs

For disc of:

∅: min. 700 mm, max. 3,500 mm

H: min. 350 mm, max. 3,000 mm

Weight to max. 60 tons

Working areas for contact technology:

X: 2,000 mm, Z: 3,000 mm

Continuous annealing line: winding and unwinding

Unwinding with retaining tension depending on the strip, and parallel intermediate strip winding of the protective film on the clamping mandrel.

Winding up with strip control of 0.8 to 25 kN and strip edge control for exact winding.

Copper pipe machining unit

Working areas: cleansing, deburring, bundling, and packing in boxes

Component measurements:

∅: min. 0 mm, max. 50 mm

L: min. 2,000 mm, max. 7,000 mm

Gate assembly device for security gates

For the world’s longest railway tunnel, the Gotthard Base Tunnel in Switzerland, which is 57 kilometres long.