WJC – clean cutting without thermal influences

Start » WJC

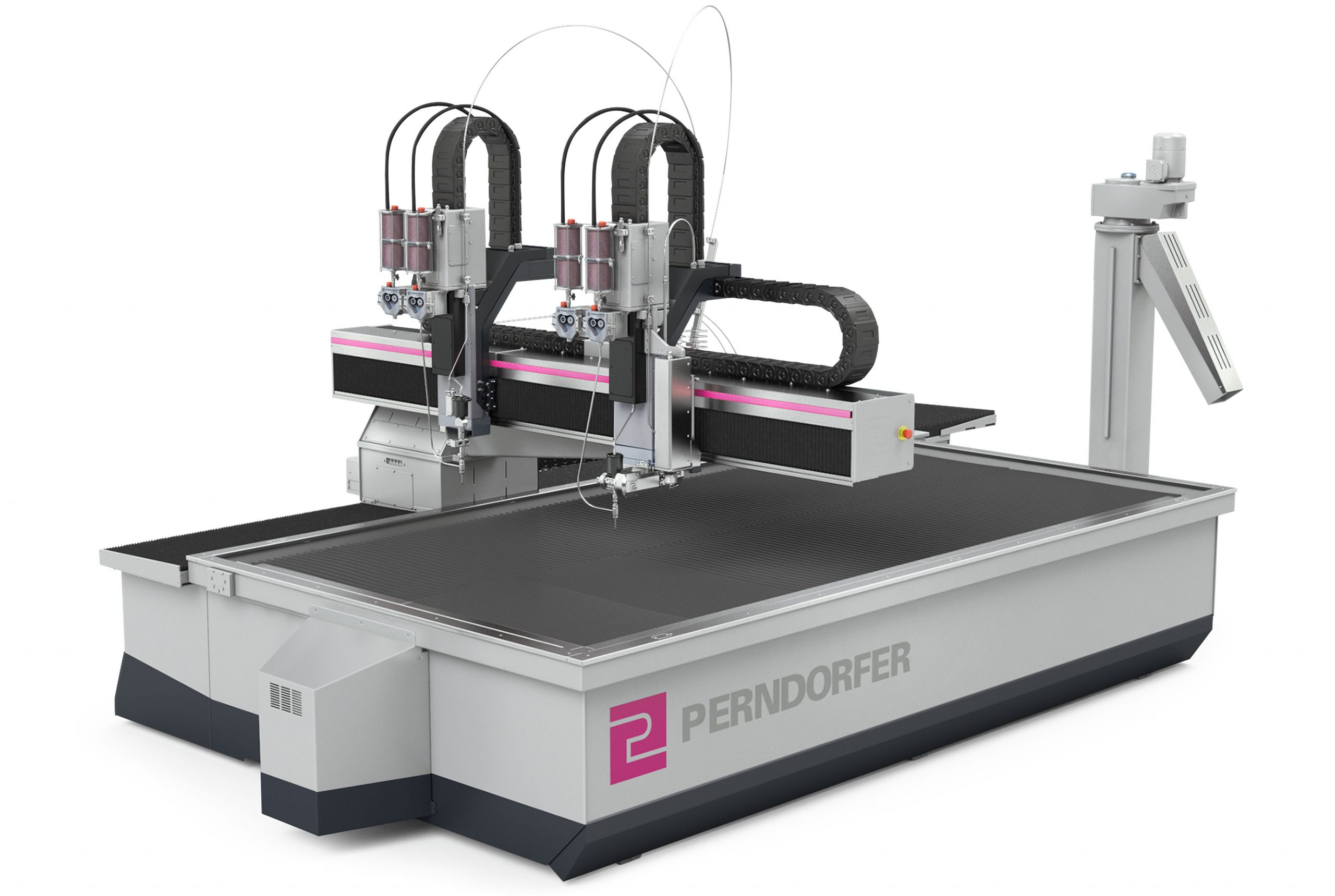

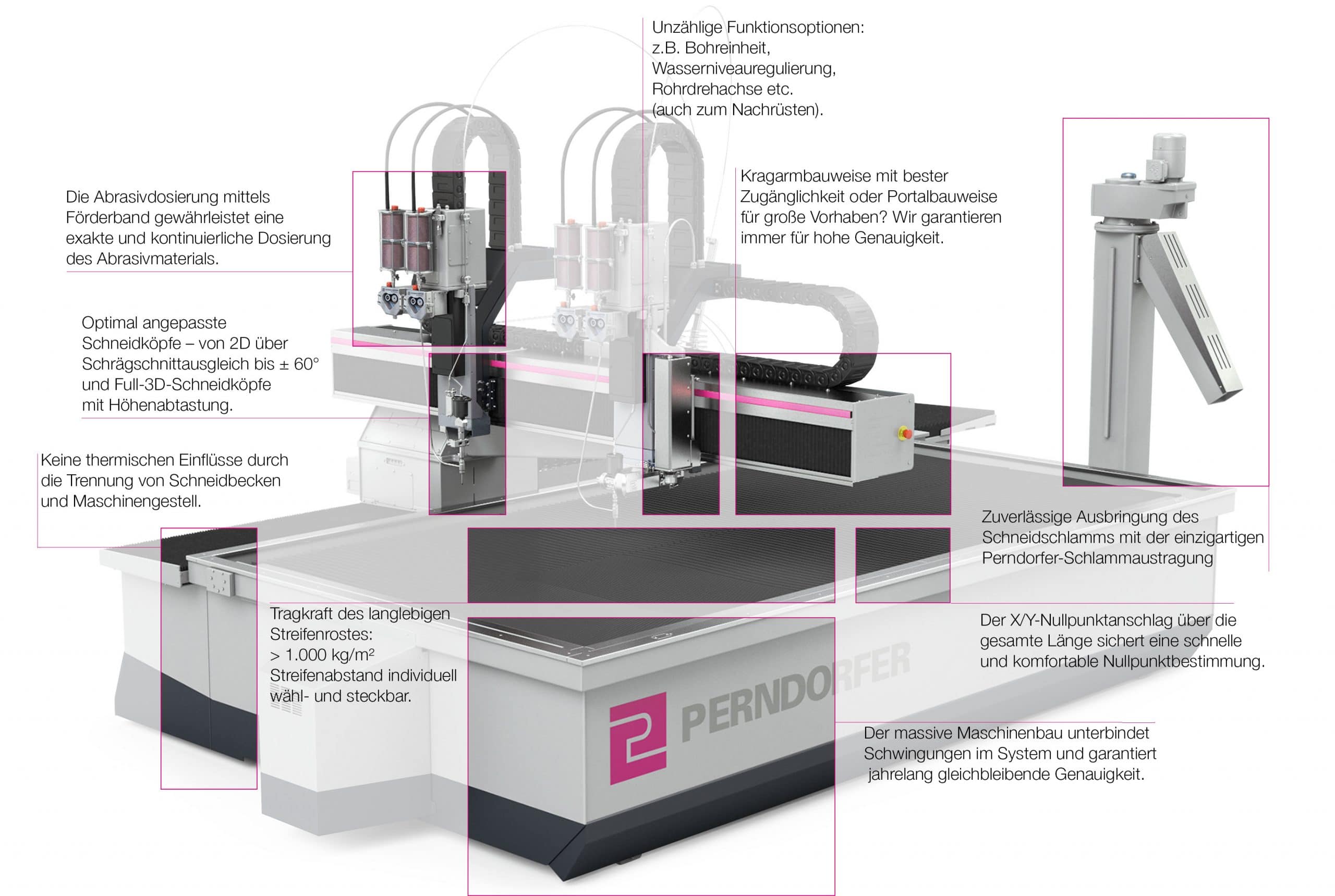

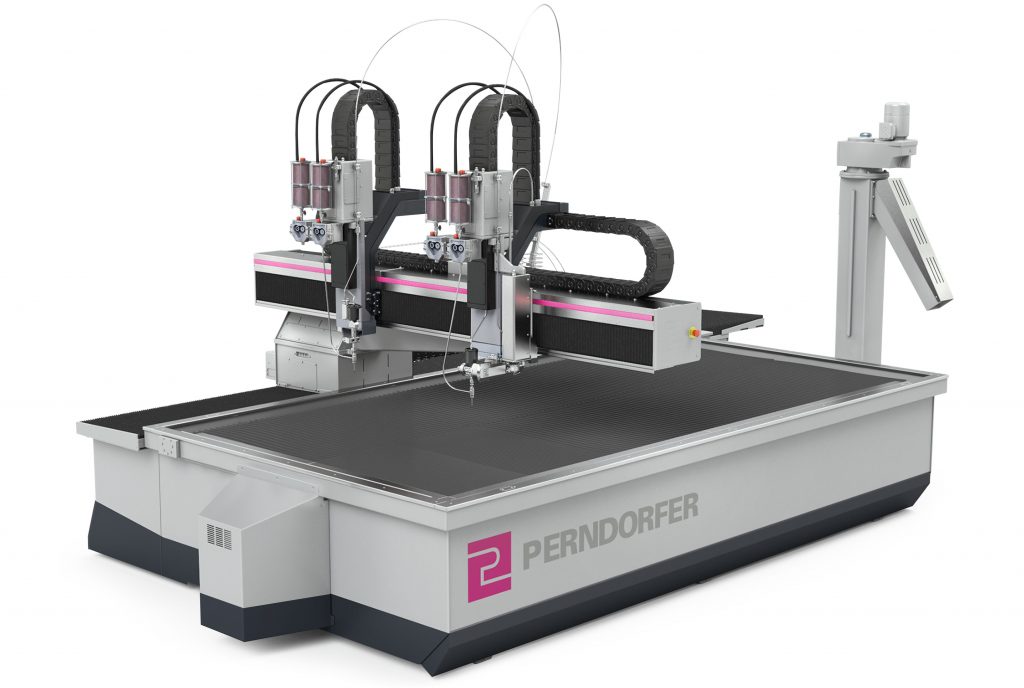

New Generation – Design 2020.

Precision means higher quality, dimension for stability, and variability for flexibility.

Waterjet cutting separates materials without using heat. This means the material is not burned, does not acquire any micro-fissures, harden, or change its shape.

Close to clients – Leader in quality and technology.

“Our product portfolio has well engineered solutions for a wide range of tasks. We like to address client wishes and special requirements and always look forward to new challenges.”

Perndorfer Maschinenbau

Quality Construction

Because waterjet cutting is a cutting process without thermal influences, the material to be cut can neither burn nor form microcracks. In the WJC-Verfahren (processing using water jet cutting), it does not harden and does not change its structure. A wide variety of soft or hard materials are cut precisely by the water cutting system. Foams, thick elastomers, polystyrene, insulating wool, leather, rubber and much more. m. is separated by pure water cutting. Harder materials such as glass, ceramics, metal, stone or plastic and composite materials require a much higher cutting force, which is generated by a water-abrasive mixture (WJC abrasive water cutting technology).