Start » WJC 3D

To work on Klopper heads, welded assemblies, complex three-dimensional geometrics, and other material with more space.

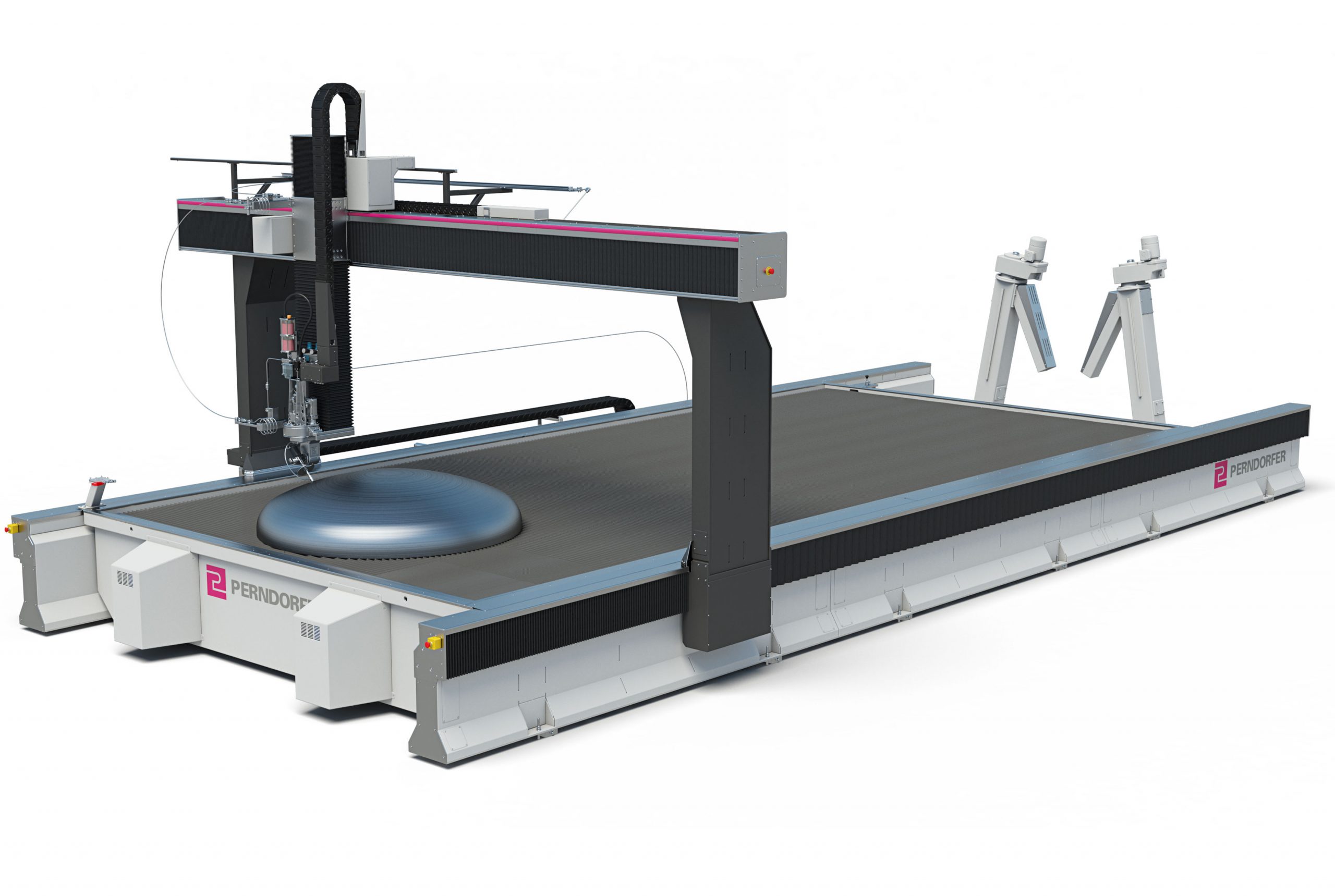

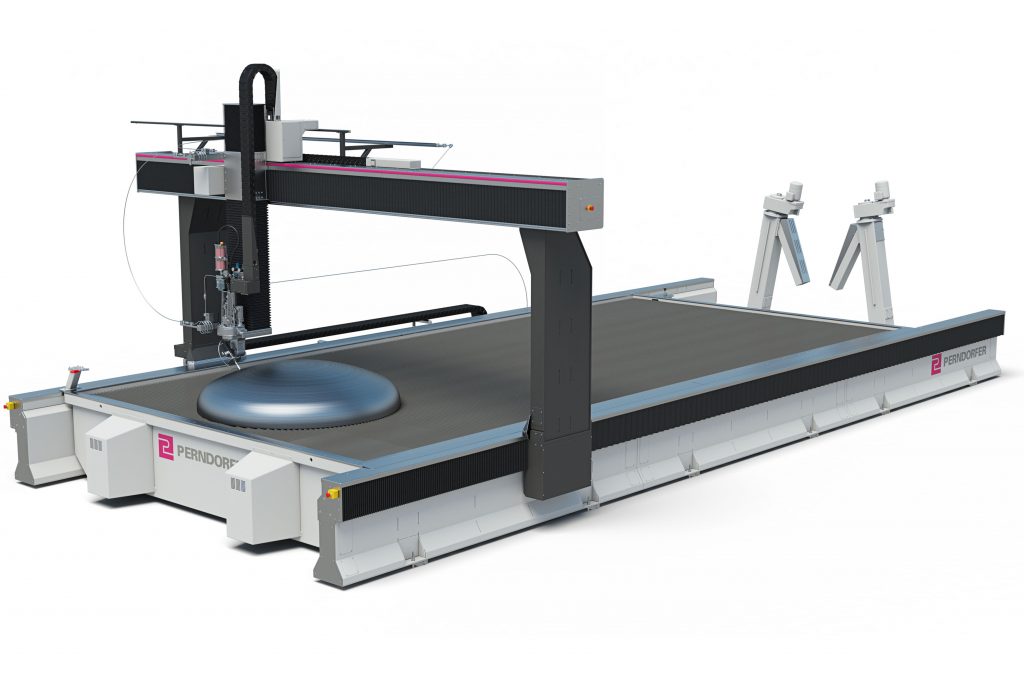

WJC 3D

This system has a large Z-axis hub and a full 3D cutting head. This gives the system an advantage in terms of accessibility and loading compared to the high-portal construction. Thanks to the large z axis hub up to 1,500 mm of Klopper heads, tubes, containers, and constructions can be worked on right on the cutting table.

Gantry design.

Working surface: 4,000 x 3,000 mm – 12,000 x 4,000 mm

Other sizes available upon request.

This application is perfect if samples from welded assemblies from various parts are to be taken using waterjet. Because no heat is added to the material, the structure of the material does not change.

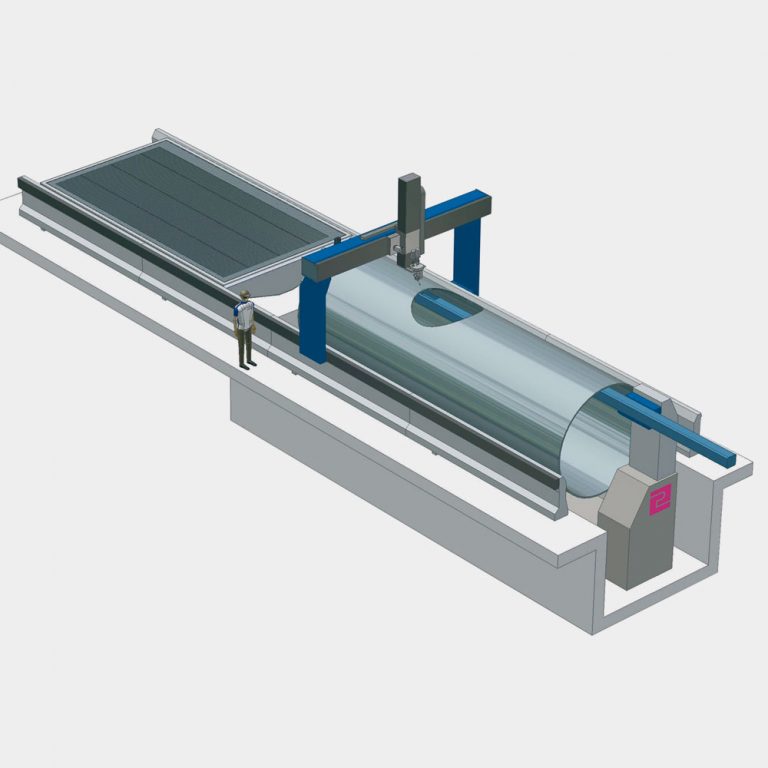

Tubes and containers up to 3,000 mm in diameter can be cut easily with this machine. Larger cutting diameters are possible as a custom design. The patented 3D abrasive head also makes it possible to cut complex contours. The 3D (5 axes) machine can be equipped with a cutting table.

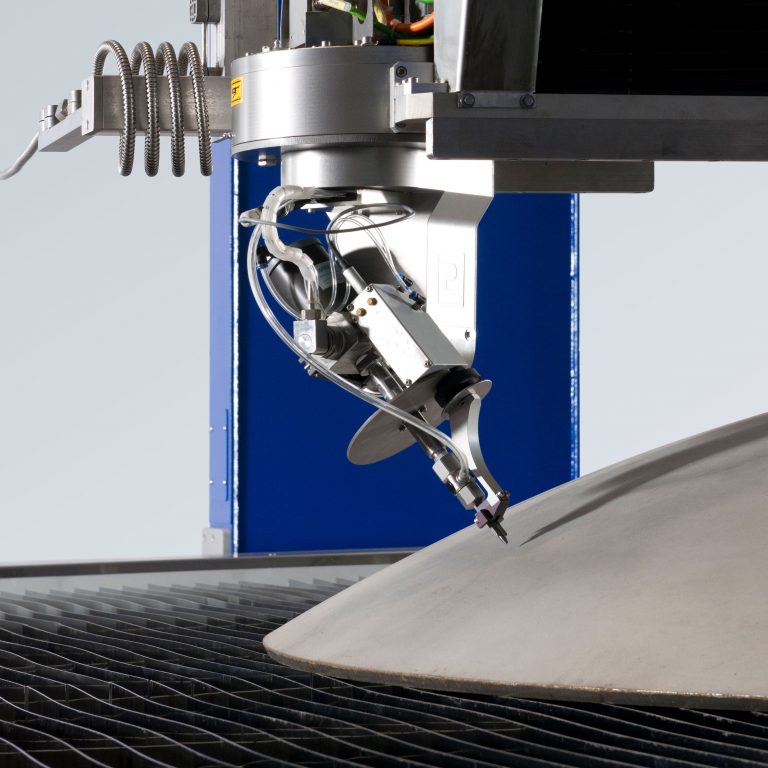

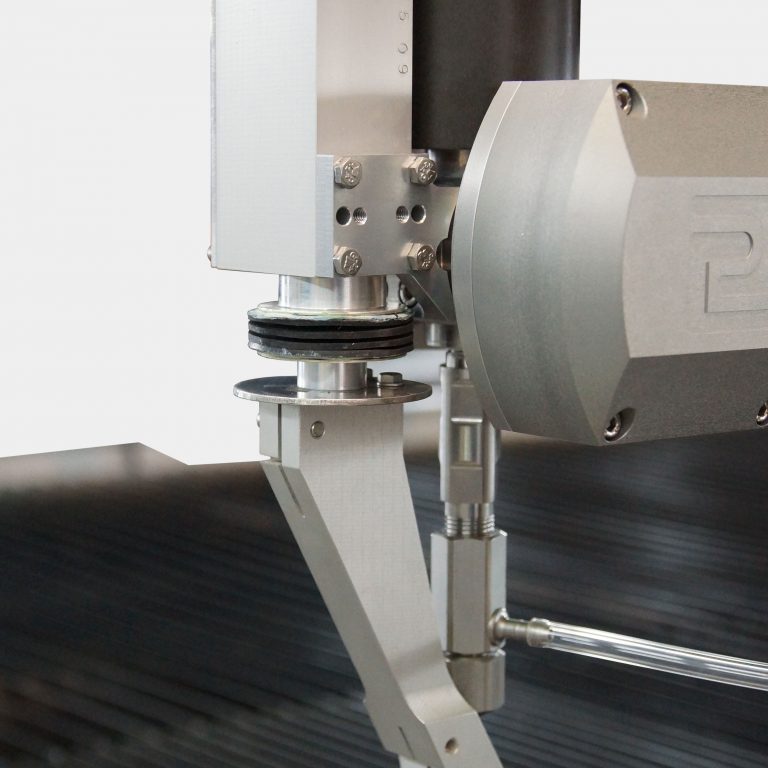

The 3D cutting head ensures an even cutting quality even with complicated contours. With the b axis cuts up to ± 130° are possible. The endlessly rotating c axis has all the advantages of the integrated abrasive technology.

The 3D height sensor makes it possible to reliably sense the material’s surface with an inclined cutting head. This ensures a constant distance from nozzle to material. It also enables high-quality bevel cuts. The 3D height sensor can also be used for straight cuts and flat material.